Green Chemistry and the UN 2030 Agenda: A Framework for Sustainable Drug Development

This article explores the critical role of green chemistry in achieving the UN 2030 Agenda for Sustainable Development, with a specific focus on applications for researchers, scientists, and drug development...

Green Chemistry and the UN 2030 Agenda: A Framework for Sustainable Drug Development

Abstract

This article explores the critical role of green chemistry in achieving the UN 2030 Agenda for Sustainable Development, with a specific focus on applications for researchers, scientists, and drug development professionals. It establishes the direct connections between the 12 Principles of Green Chemistry and specific Sustainable Development Goals (SDGs), including Good Health and Well-Being, Responsible Consumption and Production, and Climate Action. The content provides a methodological guide for implementing green chemistry in R&D, addresses common troubleshooting and optimization challenges, and validates the approach with real-world metrics and case studies from the pharmaceutical industry, demonstrating both environmental and economic benefits.

Understanding the Framework: Green Chemistry and its Direct Link to the SDGs

The UN 2030 Agenda for Sustainable Development presents an integrated framework for achieving a sustainable future, balancing environmental protection, social equity, and economic prosperity. Green chemistry, defined as the design of chemical products and processes that reduce or eliminate the use or generation of hazardous substances, emerges as a critical scientific discipline for operationalizing this agenda [1]. By proactively addressing environmental and health impacts at the molecular level, green chemistry provides the foundational tools and methodologies for researchers and industrial professionals to advance multiple Sustainable Development Goals (SDGs) simultaneously. This technical guide examines the mechanisms through which green chemistry principles directly support SDG targets related to responsible consumption and production, climate action, good health and well-being, and affordable and clean energy. For researchers in drug development and other chemical-intensive industries, adopting green chemistry frameworks is not merely an environmental consideration but a strategic imperative for innovating sustainable technologies that align with the universal call for people, planet, and prosperity.

Green Chemistry Principles and SDG Alignment

The Twelve Principles of Green Chemistry, established by Anastas and Warner, provide a systematic framework for designing chemical products and processes that minimize environmental impact and reduce resource consumption [1] [2]. These principles align directly with the targets of the UN 2030 Agenda, creating a actionable pathway for scientific research and industrial implementation. The table below delineates the connections between specific green chemistry principles and their corresponding contributions to SDG targets.

Table 1: Alignment of Green Chemistry Principles with UN Sustainable Development Goals

| Green Chemistry Principle | Primary SDG Supported | Technical Application & Contribution |

|---|---|---|

| Prevent Waste [1] | SDG 12: Responsible Consumption & Production | Designs syntheses to avoid waste generation, reducing environmental releases and resource use |

| Maximize Atom Economy [1] [3] | SDG 9: Industry, Innovation & Infrastructure | Develops efficient syntheses where most starting materials are incorporated into the final product |

| Design Less Hazardous Syntheses [1] | SDG 3: Good Health & Well-Being | Uses/generates substances with minimal toxicity to humans and ecosystems |

| Design Safer Chemicals [1] | SDG 12: Responsible Consumption & Production | Creates fully effective products with little or no toxicity |

| Use Safer Solvents/Auxiliaries [1] [2] | SDG 3: Good Health & Well-Being & SDG 6: Clean Water & Sanitation | Replaces volatile organic compounds (VOCs) and hazardous solvents with safer alternatives |

| Increase Energy Efficiency [1] [3] | SDG 7: Affordable & Clean Energy & SDG 13: Climate Action | Runs reactions at ambient temperature/pressure, uses microwave/ultrasound assistance |

| Use Renewable Feedstocks [1] [4] | SDG 7: Affordable & Clean Energy & SDG 15: Life on Land | Replaces depletable fossil fuels with agricultural products or waste streams |

| Avoid Chemical Derivatives [1] | SDG 12: Responsible Consumption & Production | Minimizes protecting groups, reducing reagent use and waste |

| Use Catalysts [1] [3] | SDG 9: Industry, Innovation & Infrastructure | Employs catalytic rather than stoichiometric reagents to minimize waste |

| Design for Degradation [1] | SDG 14: Life Below Water & SDG 15: Life on Land | Creates products that break down into innocuous substances after use |

| Real-time Analysis for Pollution Prevention [1] | SDG 9: Industry, Innovation & Infrastructure | Implements in-process monitoring to control and minimize byproducts |

| Minimize Accident Potential [1] | SDG 8: Decent Work & Economic Growth | Designs chemicals and physical forms to reduce risks of explosions, fires, and releases |

Quantitative Impact Assessment of Green Chemistry Innovations

The implementation of green chemistry principles has yielded measurable environmental and economic benefits across multiple industries, particularly in pharmaceuticals. The following table summarizes documented outcomes from industrial case studies, providing quantitative evidence of green chemistry's contribution to SDG targets.

Table 2: Quantitative Impacts of Green Chemistry in Industrial Applications

| Industry/Company | Innovation | Documented Quantitative Impact | Relevant SDG |

|---|---|---|---|

| Pharmaceutical (Merck & Co.) [2] | Greener synthesis of Letermovir (antiviral drug) | 60% increase in overall yield, 93% reduction in raw material cost, 90% reduction in water usage, 89% reduction in carbon footprint. Estimated 15,000 MT of waste reduction over drug's lifetime. | SDG 9, SDG 12, SDG 13 |

| Pharmaceutical (Pfizer) [2] | Improved synthesis of Pregabalin (Lyrica) using biocatalysis | 90% reduction in solvent usage, 50% reduction in raw materials, energy savings equivalent to ~3 million tons of CO₂ emissions. | SDG 7, SDG 9, SDG 12 |

| US Drug Industry (EPA Analysis) [2] | Adoption of green chemistry principles | 50% decrease in VOC use between 2004-2013; 7% decrease in chemical waste releases to air, land, and water. | SDG 3, SDG 12 |

| Plastics (Newlight Technologies) [2] | Aircarbon thermoplastic from methane emissions | Nine-fold yield increase, cost reduction by a factor of three, production of carbon-negative plastic. | SDG 9, SDG 12, SDG 13 |

| Chemicals (BASF) [2] | Greener synthesis of Ibuprofen | Atom efficiency nearly doubled; number of synthesis steps reduced by half. | SDG 9, SDG 12 |

| BASF - BASIL Process [2] | Bi-phasic Acid scavenging utilizing ionic liquids | Yield increased from 50% to 98% for photoinitiator precursor. | SDG 9, SDG 12 |

Experimental Protocols for Green Chemistry Methodologies

Protocol: Biocatalytic Synthesis in Pharmaceutical Manufacturing

Biocatalysis utilizes natural catalysts, such as enzymes, to perform specific chemical transformations under mild conditions, aligning with multiple green chemistry principles [2]. This protocol is adapted from the greener synthesis of Pregabalin, demonstrating the replacement of a classical resolution process.

- Objective: To achieve enantioselective synthesis efficiently using enzyme catalysis, eliminating the need for resolution and reducing waste.

- Materials:

- Procedure:

- Reaction Setup: Charge the bioreactor with the substrate and the selected solvent.

- Biocatalyst Addition: Introduce the enzyme catalyst. Catalysts are effective in small amounts and carry out a single reaction many times, minimizing waste [1].

- Process Conditions: Maintain the reaction at ambient temperature (25-40°C) and pH 7-8. The use of mild conditions is a key energy efficiency strategy [3].

- Process Monitoring: Use in-process, real-time monitoring (e.g., HPLC) to track reaction progress and minimize byproduct formation [1].

- Product Isolation: Upon completion, separate the product, often requiring less intensive purification due to high selectivity.

- Catalyst Recovery: Recover and recycle the enzyme catalyst for subsequent batches where feasible.

- Green Chemistry Advantages: This method demonstrates the principle of using catalysts, not stoichiometric reagents [1]. It typically operates with high atom economy, under milder and less energy-intensive conditions, and with reduced solvent requirements compared to traditional synthetic routes [2].

Protocol: Solvent Replacement Strategy for Safer Chemical Processing

This methodology outlines a systematic approach for replacing hazardous solvents with safer alternatives, a critical step for reducing toxicity and waste [2].

- Objective: To identify and validate a greener solvent that maintains reaction efficiency while improving environmental, health, and safety (EHS) profiles.

- Materials:

- Procedure:

- Hazard Assessment: Evaluate the current solvent's EHS properties, including flammability, toxicity, and environmental persistence [2].

- Alternative Identification: Screen solvent databases or guides (e.g., CHEM21 Solvent Selection Guide) for safer alternatives with similar physicochemical properties.

- Bench-Scale Testing: Perform the target reaction in candidate green solvents at a small scale.

- Performance Evaluation: Quantify key metrics: reaction yield, reaction rate, product purity, and ease of product isolation.

- Life Cycle Assessment (LCA): Conduct a comparative LCA for the top-performing solvent candidates to understand the broader environmental impact, including energy use for separation and recycling [4].

- Process Optimization & Scale-Up: Optimize reaction parameters (e.g., temperature, concentration) for the selected green solvent and validate at pilot scale.

- Green Chemistry Advantages: Directly applies the principle of using safer solvents and reaction conditions [1]. This can lead to a reduced potential for accidents, lower VOC emissions, and often decreased energy use for separation and disposal.

Research Reagent Solutions: A Scientist's Toolkit

The implementation of green chemistry requires a shift in the materials and reagents used in research and development. The following table catalogs key reagent solutions that enable sustainable experimental design.

Table 3: Essential Research Reagents and Materials for Green Chemistry Applications

| Reagent/Material | Function | Green Advantage & Example Application |

|---|---|---|

| Biocatalysts (Enzymes) [2] | Catalyze specific chemical transformations (e.g., hydrolysis, reduction). | Biodegradable, work under mild conditions, highly selective. Used in Pfizer's synthesis of Pregabalin to avoid wasteful resolution steps. |

| Heterogeneous Catalysts [3] | Solid-phase catalysts for reactions like hydrogenation. | Easily separated from reaction mixtures and reusable, minimizing waste. |

| Ionic Liquids [2] | Serve as non-volatile solvents or catalysts. | Low vapor pressure reduces airborne emissions. Used in the BASF BASIL process as a safer medium. |

| Supercritical CO₂ (scCO₂) [3] | Non-toxic, non-flammable solvent for extraction and reactions. | Replaces hazardous organic solvents. Easily removed by depressurization, leaving no residue. |

| Renewable Feedstocks (e.g., plant-based sugars, lipids) [4] [2] | Starting materials for synthesis of chemicals, polymers, and biofuels. | Reduce dependence on depletable fossil fuels. Used to produce bioplastics like PLA and Aircarbon. |

| Water as a Solvent [3] | Benign reaction medium for aqueous-phase chemistry. | Non-toxic, non-flammable, inexpensive, and readily available. |

| Microwave Reactors [3] | Provide rapid, uniform heating for chemical reactions. | Significantly reduce reaction times and energy consumption compared to conventional heating. |

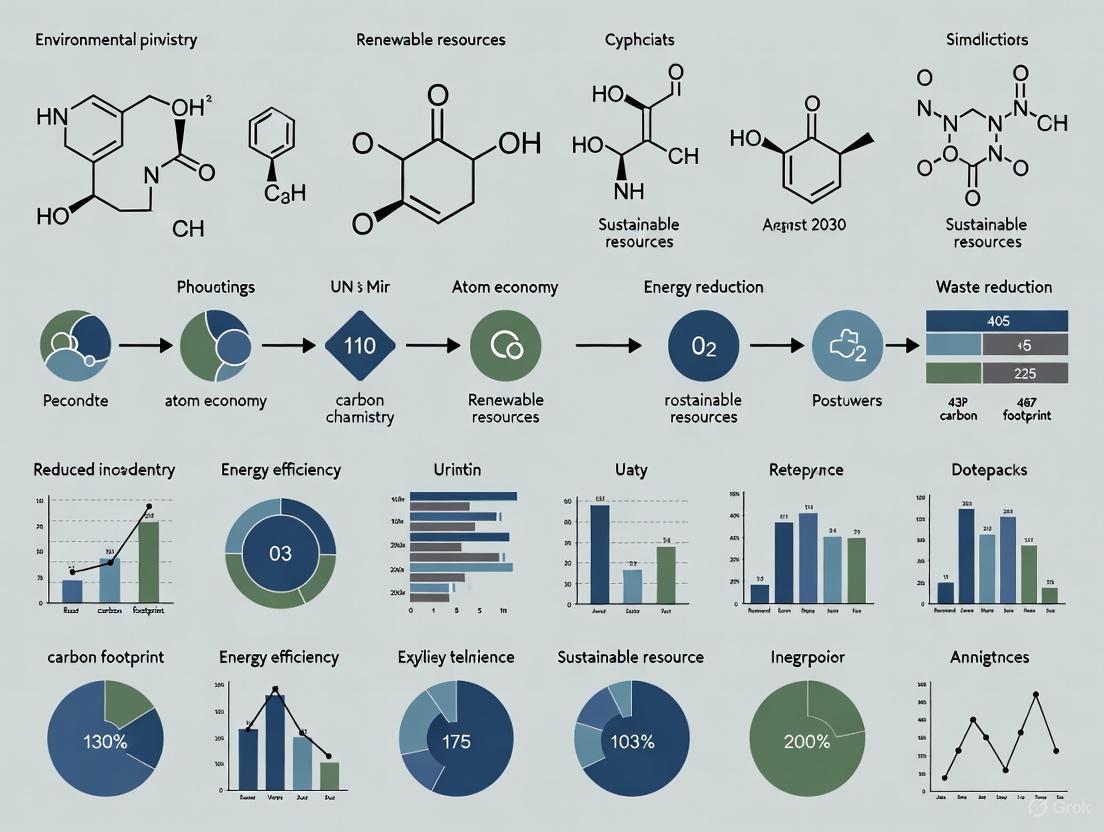

Strategic Workflow for Green Chemistry Implementation

The following diagram illustrates a strategic workflow for research and development teams to integrate green chemistry principles into the design and optimization of chemical processes, ensuring alignment with the SDGs.

Strategic Green Chemistry R&D Workflow

Green chemistry provides the scientific and technical foundation necessary to achieve the ambitious targets of the UN 2030 Agenda. By integrating principles such as waste prevention, atom economy, and the use of renewable feedstocks into research and development, scientists and drug development professionals can design chemical products and processes that are inherently sustainable. The quantitative successes in the pharmaceutical and materials industries demonstrate that this approach yields both significant environmental benefits and economic advantages. As the chemical industries continue to innovate, the continued application of green chemistry will be indispensable for building a healthier, more sustainable, and prosperous future for all, fully aligning scientific progress with the universal call for people, planet, and prosperity.

Green chemistry, defined as the design of chemical products and processes that reduce or eliminate the use or generation of hazardous substances, represents a fundamental shift in how chemists approach molecular design and manufacturing [1]. Unlike traditional pollution cleanup efforts that address waste after it is created, green chemistry focuses on preventing pollution at the molecular level through innovative scientific solutions [1]. This proactive approach transforms chemistry from a source of environmental challenges into a powerful engine for achieving the United Nations' 2030 Agenda for Sustainable Development.

The framework of green chemistry is built upon twelve guiding principles that together provide a comprehensive design philosophy for sustainability [2]. These principles encompass all stages of a chemical product's life cycle—from initial design and manufacture through ultimate disposal—enabling researchers and industrial professionals to embed sustainability into their work's very DNA [1]. As global challenges such as climate change, resource scarcity, and pollution accelerate, the adoption of green chemistry principles becomes increasingly urgent for creating a technically advanced, economically viable, and environmentally responsible chemical industry.

The 12 Principles of Green Chemistry: Framework and Implementation

The twelve principles of green chemistry provide a systematic framework for designing chemical products and processes that reduce their environmental footprint and intrinsic hazards [1]. The following table presents the complete set of principles with technical explanations of their significance and implementation approaches.

Table 1: The 12 Principles of Green Chemistry with Technical Explanations

| Principle | Technical Explanation & Implementation |

|---|---|

| 1. Prevent Waste | Design syntheses to prevent waste generation rather than treating or cleaning up after formation. |

| 2. Maximize Atom Economy | Design syntheses so final products incorporate maximum proportion of starting materials; minimize atom waste. |

| 3. Design Less Hazardous Syntheses | Use and generate substances with minimal toxicity to humans and environment while maintaining functionality. |

| 4. Design Safer Chemicals | Design effective chemical products with minimal toxicity. |

| 5. Use Safer Solvents/Conditions | Avoid auxiliary substances; use safer solvents when necessary. |

| 6. Increase Energy Efficiency | Conduct reactions at ambient temperature/pressure when possible; assess environmental/economic impacts. |

| 7. Use Renewable Feedstocks | Use starting materials from renewable resources (e.g., agricultural waste) rather than depletable feedstocks. |

| 8. Avoid Chemical Derivatives | Avoid unnecessary derivatization (blocking/protecting groups) requiring additional reagents/generating waste. |

| 9. Use Catalysts | Use catalytic reactions with minimal waste; catalysts are effective in small amounts for multiple reactions. |

| 10. Design for Degradation | Design chemical products to break down to innocuous substances after use to prevent environmental accumulation. |

| 11. Analyze in Real Time | Develop real-time in-process monitoring and control to prevent hazardous substance formation. |

| 12. Minimize Accident Potential | Design chemicals and physical forms to minimize potential for accidents (explosions, fires, environmental releases). |

These principles work synergistically to create a holistic approach to sustainable chemical design. Rather than operating in isolation, they form an interconnected framework where advancements in one principle often facilitate improvements in others. For example, designing safer chemicals that degrade after use (Principles 4 and 10) naturally supports the responsible consumption and production targets outlined in UN Sustainable Development Goal 12 [5].

Green Chemistry and the UN Sustainable Development Goals

Green chemistry serves as a critical enabling science for achieving multiple UN Sustainable Development Goals (SDGs) by providing practical methodologies to address global challenges while fostering economic development [5]. The following diagram illustrates the interconnectedness between green chemistry principles and specific SDGs.

The application of green chemistry directly advances SDG 9 by fostering resilient infrastructure, promoting inclusive and sustainable industrialization, and encouraging innovation through the development of more efficient chemical processes [5]. For instance, the adoption of catalytic reactions and renewable feedstocks in chemical manufacturing enables industries to reduce their environmental footprint while maintaining economic competitiveness.

The "Green Chemistry for Life" initiative, a partnership between UNESCO, PhosAgro, and IUPAC, exemplifies how green chemistry supports sustainable development through international cooperation [6]. This project provides grants to young scientists worldwide for research on green chemistry technologies that address environmental and health challenges, directly contributing to SDG 17 (Partnerships for the Goals) while also advancing multiple other SDGs through scientific innovation [6].

Current Trends and Industrial Applications in Green Chemistry

Emerging Green Technologies

Green chemistry is rapidly evolving from an academic concept to an industrial reality, driven by both environmental imperatives and economic opportunities [7]. Several key technological trends are shaping its implementation across pharmaceutical, materials, and energy sectors:

Mechanochemistry: This solvent-free approach uses mechanical energy through grinding or ball milling to drive chemical reactions, significantly reducing waste and enhancing safety [8]. Mechanochemistry enables conventional and novel transformations, including those involving low-solubility reactants or compounds unstable in solution, with applications in pharmaceutical synthesis, polymer production, and advanced materials development [8].

Water-Based Reactions: Traditionally considered unsuitable for organic synthesis, water is now recognized as a viable solvent for many reactions [8]. Recent breakthroughs demonstrate that many reactions can occur in or on water, leveraging water's unique hydrogen bonding, polarity, and surface tension to facilitate chemical transformations [8]. This approach eliminates the need for toxic organic solvents, reduces production costs, and makes chemical synthesis more accessible in low-resource settings.

Renewable Feedstocks and Circular Economy: The shift from petroleum-based feedstocks to bio-based alternatives represents a fundamental transformation in chemical manufacturing [7]. Companies are increasingly using ethanol from sugarcane, algal oils, and agricultural waste to produce polymers for packaging, construction, and automotive applications [7]. This aligns with circular economy models that emphasize waste reduction, material recovery, and designing products with end-of-life considerations from the outset.

Quantitative Impact of Green Chemistry Implementation

The adoption of green chemistry principles has yielded significant measurable benefits across multiple industries. The following table summarizes documented environmental and economic impacts from award-winning green chemistry implementations.

Table 2: Quantitative Impacts of Green Chemistry Implementation in Industry

| Application/Company | Green Chemistry Innovation | Documented Impact |

|---|---|---|

| Merck & Co. [9] | Biocatalytic process for HIV-1 antiviral Islatravir | Replaced 16-step clinical route with single biocatalytic cascade; eliminated organic solvents |

| 2025 Green Chemistry Challenge Award Winners (Cumulative) [9] | Various technologies across categories | Eliminated 830 million lb hazardous chemicals/solvents; saved 21 billion gal water; prevented 7.8 billion lb CO2 releases |

| Pfizer [2] | Greener synthesis of Pregabalin (Lyrica) | 90% reduction in solvent usage; 50% reduction in raw materials |

| BASF [2] | Greener synthesis of Ibuprofen | Halved number of synthesis steps; doubled atom efficiency; increased yield from 50% to 98% |

| U.S. Drug Industry [2] | Adoption of green chemistry principles (2004-2013) | 50% decrease in VOC use; 7% decrease in chemical waste releases |

The cumulative impact of these innovations demonstrates that green chemistry achieves more than environmental benefits—it also delivers substantial economic value through reduced material and energy costs, decreased waste disposal expenses, and improved process efficiency [2]. For instance, Merck's green synthesis of Letermovir resulted in a 60% increase in overall yield, 93% reduction in raw material costs, and 90% reduction in water usage [2].

Experimental Methodologies and Research Protocols

Solvent-Free Synthesis Using Mechanochemistry

Mechanochemistry represents a paradigm shift in chemical synthesis by eliminating the need for solvents, which traditionally account for the majority of waste in pharmaceutical and fine chemical production [8]. The following workflow illustrates a typical mechanochemical synthesis procedure using ball milling.

This methodology has been successfully applied to synthesize various materials, including solvent-free imidazole-dicarboxylic acid salts for use as proton-conducting electrolytes in fuel cells [8]. The mechanochemical approach provided high yields while significantly reducing solvent usage and energy consumption compared to traditional solution-based synthesis [8].

Research Reagent Solutions for Green Chemistry

Implementing green chemistry principles requires specific reagents and materials that minimize environmental impact while maintaining functionality. The following table details key research reagents that enable greener chemical synthesis.

Table 3: Green Chemistry Research Reagents and Their Applications

| Reagent/Material | Function | Green Chemistry Advantage |

|---|---|---|

| Nickel Catalysts (air-stable) [9] | Catalyze cross-coupling reactions for pharmaceutical synthesis | Replaces expensive/rare palladium; air stability eliminates energy-intensive handling |

| Deep Eutectic Solvents (DES) [8] | Customizable solvents for extraction and synthesis | Biodegradable, low-toxicity alternative to conventional organic solvents |

| Biocatalysts (Enzymes) [2] | Enable specific transformations under mild conditions | Biodegradable, renewable catalysts with high selectivity; work in aqueous environments |

| Silver Nanoparticles (synthesized in water) [8] | Catalytic and antimicrobial applications | Plasma-driven synthesis in aqueous medium avoids toxic reducing agents |

| Tetrataenite (FeNi) [8] | Rare-earth-free permanent magnets | Uses abundant elements (iron, nickel); eliminates need for environmentally damaging rare-earth mining |

These reagent solutions exemplify how green chemistry principles translate into practical research tools. For instance, the development of air-stable nickel catalysts by Keary Engle at Scripps Research Institute provides a more cost-effective and sustainable alternative to traditional palladium catalysts, which are not only expensive but also require energy-intensive handling procedures to maintain stability [9].

Educational Frameworks and Professional Implementation

The growing importance of green chemistry has spurred the development of dedicated educational programs designed to prepare the next generation of chemists with sustainability-minded expertise. Universities worldwide now offer specialized courses and degrees, such as the MChem (Hons) Chemistry, Green Principles and Sustainable Processes at the University of York, which focuses on "designing more sustainable chemical products and processes for the future" [10].

These academic programs address a critical workforce development need as industries increasingly seek chemists with expertise in sustainable practices [7]. Students learn to apply green chemistry principles across various domains, including renewable energy, waste valorization, and biomass-derived materials, through research projects in specialized centers like the Green Chemistry Centre of Excellence [10].

Beyond formal education, professional recognition programs like the Green Chemistry Challenge Awards play a vital role in accelerating adoption of sustainable practices by highlighting successful implementations and establishing best practices [9]. These awards recognize innovations across multiple categories, including greener synthetic pathways, design of safer chemicals, and climate change technologies, providing both inspiration and practical models for industrial implementation [9].

The twelve principles of green chemistry provide a comprehensive framework for aligning chemical research and industrial practice with the goals of sustainable development. As demonstrated through numerous case studies and quantitative metrics, the implementation of these principles delivers measurable environmental benefits while maintaining economic viability [2] [9]. The ongoing evolution of green chemistry—from academic concept to industrial imperative—reflects its essential role in addressing global challenges such as climate change, resource depletion, and environmental pollution.

For researchers, scientists, and drug development professionals, green chemistry represents both a responsibility and an opportunity. By integrating these principles into daily practice, the chemical enterprise can continue to drive innovation and economic growth while safeguarding human health and the environment for future generations. As the field continues to advance through emerging technologies like AI-guided reaction optimization, biocatalysis, and circular manufacturing systems, green chemistry will play an increasingly critical role in achieving the UN 2030 Agenda for Sustainable Development, proving that environmental responsibility and economic progress are not just compatible but mutually reinforcing.

The 2030 Agenda for Sustainable Development, with its 17 Sustainable Development Goals (SDGs), presents a universal call to action to end poverty, protect the planet, and ensure prosperity for all by 2030 [11]. Within this framework, green chemistry emerges as a fundamental discipline that enables transformative progress across multiple SDGs through molecular innovation. By designing chemical products and processes that reduce or eliminate the generation and use of hazardous substances, green chemistry provides the foundational tools to address complex challenges at the intersection of human health, environmental protection, and economic development [12]. This technical guide examines the strategic mapping of green chemistry principles to specific SDG targets, offering researchers and drug development professionals a framework for aligning molecular design with global sustainability imperatives.

Molecular Design Principles Supporting SDG Implementation

The Foundation of Green Chemistry in Sustainable Development

Green chemistry principles provide a systematic approach for designing chemical syntheses and processes that minimize environmental impact while maximizing efficiency and safety [12]. These principles align directly with the SDGs by offering concrete methodologies to achieve sustainability targets. The twelve principles of green chemistry—including atom economy, waste prevention, safer solvents, and renewable feedstocks—serve as a blueprint for developing technologies that support sustainable development across sectors [13].

The connection between molecular-level decisions and global sustainability outcomes represents a paradigm shift in chemical research and development. By integrating green chemistry principles at the earliest stages of molecular design, chemists can create innovative solutions that address multiple SDGs simultaneously through cascading, non-linear benefits [14]. This systems-thinking approach recognizes that advancements in green chemistry can trigger positive ripple effects across the sustainability landscape, from climate action to human health protection.

Strategic Mapping to High-Impact SDGs

Green chemistry principles demonstrate particularly strong alignment with seven key SDGs where molecular innovation delivers transformative impact:

Table 1: Green Chemistry Alignment with Priority Sustainable Development Goals

| SDG | Chemical Innovation Focus Areas | Green Chemistry Principles Applied |

|---|---|---|

| SDG 2: Zero Hunger [11] | Sustainable fertilizers, crop protection agents, food preservation technologies | Waste prevention, safer chemicals for accident prevention, design for degradation |

| SDG 3: Good Health & Well-Being [11] | Green pharmaceutical synthesis, pollution reduction, safer materials | Safer solvents, renewable feedstocks, inherently benign design |

| SDG 6: Clean Water & Sanitation [11] | Water purification, desalination, pollution prevention | Real-time pollution prevention, analytical methodology, catalyst design |

| SDG 7: Affordable & Clean Energy [11] | Energy storage materials, renewable energy technologies, efficiency improvements | Energy efficiency, renewable feedstocks, catalysis |

| SDG 9: Industry, Innovation & Infrastructure [11] | Sustainable manufacturing processes, advanced materials, circular systems | Atom economy, waste prevention, inherently safer chemistry |

| SDG 12: Responsible Consumption & Production [11] [15] | Circular economy, sustainable materials management, waste valorization | Design for degradation, recycle, and reuse; process intensification |

| SDG 13: Climate Action [11] | Carbon capture and utilization, low-carbon technologies, climate resilience | CO₂ as feedstock, energy efficiency, renewable feedstocks |

The following diagram illustrates the interconnectedness of green chemistry principles with these seven priority SDGs:

Experimental Frameworks: Green Chemistry Methodologies for SDG Implementation

Metal-Free Synthetic Protocols for Pharmaceutical Applications

Traditional synthetic methodologies often rely on transition metals that pose toxicity concerns and environmental persistence issues [12]. Recent advances in metal-free catalysis demonstrate how green chemistry principles support SDG 3 (Good Health and Well-Being) through safer pharmaceutical synthesis while simultaneously advancing SDG 12 (Responsible Consumption and Production) by reducing hazardous waste.

Experimental Protocol: Metal-Free Oxidative C–H Amination of Benzoxazoles

- Objective: Synthesis of 2-aminobenzoxazoles without transition metal catalysts

- Reaction Setup:

- Substrate: Benzoxazole derivatives (1.0 equiv)

- Catalyst: Tetrabutylammonium iodide (TBAI, 20 mol%)

- Oxidant: Aqueous tert-butyl hydroperoxide (TBHP, 2.0 equiv) or H₂O₂

- Additive: Acetic acid (1.5 equiv)

- Conditions: Room temperature, 6-12 hours

- Methodology:

- Charge reaction vessel with benzoxazole substrate and TBAI catalyst

- Add acetic acid as reaction medium and promoter

- Slowly add aqueous oxidant (TBHP or H₂O₂) with stirring

- Monitor reaction progress by TLC or LC-MS

- Upon completion, extract with ethyl acetate or alternative green solvent

- Purify by recrystallization or column chromatography

- Key Advantages:

- Eliminates copper, silver, or cobalt catalysts

- Utilizes aqueous oxidants instead of stoichiometric metal-based oxidants

- Achieves yields of 82-97% comparable to traditional methods

- Operates under mild conditions (room temperature)

This methodology demonstrates superior sustainability metrics compared to conventional approaches employing Cu(OAc)₂ and K₂CO₃, which present significant hazards to skin, eyes, and respiratory systems [12].

Green Solvent Systems and Renewable Feedstocks

The development of alternative reaction media represents a critical advancement toward SDG 12 targets on responsible consumption and production. Ionic liquids (ILs) and bio-based solvents offer environmentally benign alternatives to conventional volatile organic compounds.

Experimental Protocol: Ionic Liquid-Mediated C–N Bond Formation

- Objective: Develop recyclable catalytic systems for heterocycle synthesis

- Reaction System:

- Catalyst: 1-butylpyridinium iodide ([BPy]I, 30 mol%)

- Oxidant: tert-butyl hydroperoxide (TBHP, 2.0 equiv)

- Solvent: Acetic acid additive, solvent-free conditions

- Conditions: Room temperature, 8-24 hours

- Methodology:

- Combine substrate and ionic liquid catalyst in reaction vessel

- Add acetic acid as promoter (substrate:acetic acid 1:1.5 ratio)

- Introduce TBHP oxidant slowly with efficient mixing

- Monitor reaction by analytical methods (NMR, LC-MS)

- Upon completion, extract product with minimal solvent

- Recover ionic liquid catalyst by aqueous extraction and reuse for multiple cycles

- Key Advantages:

- Ionic liquids demonstrate high thermal stability and negligible vapor pressure

- Catalyst recycling potential reduces waste generation

- Enhanced reaction efficiency with yields improved to 82-97% from traditional 75%

- Eliminates hazardous solvent use through solvent-free or near-solvent-free conditions

Biotechnology and Waste Valorization Pathways

The integration of biotechnology with chemical synthesis creates powerful pathways for achieving SDG 9 (Industry, Innovation and Infrastructure) through novel bio-based production systems while supporting SDG 13 (Climate Action) through carbon emission reduction.

Experimental Protocol: Lignin Valorization to Platform Chemicals

- Objective: Convert lignin-derived biphenyl dimers to valuable chemical intermediates

- Biological System:

- Microorganism: Pseudomonas putida KT2440

- Substrate: Lignin-derived dimeric compounds (DDVA)

- Media: Minimal salt media with lignin substrate as carbon source

- Conditions: Aerobic, 30°C, 48-72 hours

- Methodology:

- Cultivate P. putida in appropriate growth medium

- Harvest cells at mid-logarithmic growth phase

- Resuspend in reaction buffer containing lignin-derived substrate

- Incubate with efficient aeration and mixing

- Monitor substrate consumption and product formation

- Extract 5-carboxyvanillic acid (5CVA) product from fermentation broth

- Key Advantages:

- Converts waste lignin stream to value-added products

- Provides renewable aromatic chemical feedstocks

- Reduces dependence on fossil-based precursors

- Demonstrates circular economy principles in chemical production

The following workflow illustrates the integrated experimental approach for implementing green chemistry methodologies:

The Research Toolkit: Essential Reagents and Materials for SDG-Aligned Chemistry

Table 2: Green Chemistry Reagent Solutions for Sustainable Research

| Reagent/Material | Function | Traditional Hazardous Alternative | SDG Relevance |

|---|---|---|---|

| Dimethyl Carbonate (DMC) [12] | Green methylating agent, solvent | Dimethyl sulfate, methyl halides | SDG 3, SDG 12 |

| Ionic Liquids (e.g., [BPy]I) [12] | Recyclable reaction media, catalysts | Volatile organic solvents | SDG 9, SDG 12 |

| Polyethylene Glycol (PEG) [12] | Phase-transfer catalyst, green solvent | Toxic phase-transfer catalysts | SDG 3, SDG 12 |

| Hypervalent Iodine Reagents [12] | Metal-free oxidants | Transition metal oxidants | SDG 3, SDG 6 |

| Deep Eutectic Solvents [16] | Biodegradable solvent systems | Halogenated solvents | SDG 12, SDG 14 |

| Mo-doped Fe-based MOF [16] | Water-splitting catalysis | Precious metal catalysts | SDG 7, SDG 13 |

| Enzyme Carbonaceous Cathode [17] | Bioelectrocatalysis | Metal-based electrodes | SDG 9, SDG 12 |

| Magnetic Polyoxometalate Catalysts [16] | Recyclable biomass fractionation | Homogeneous acid catalysts | SDG 9, SDG 12 |

Quantitative Metrics and Impact Assessment

Sustainability Performance of Green Chemistry Innovations

Table 3: Comparative Analysis of Green versus Traditional Chemical Methodologies

| Methodology | Traditional Approach | Green Chemistry Innovation | Sustainability Improvement |

|---|---|---|---|

| 2-Aminobenzoxazole Synthesis [12] | Cu(OAc)₂ catalyst, hazardous reagents | Metal-free TBAI/TBHP system | Eliminates toxic metals, increases yield (75% to 97%) |

| Isoeugenol Methyl Ether Production [12] | NaOH/KOH strong bases, high temperature | DMC/PEG mild conditions | 94% yield vs. 83%, reduced hazard profile |

| Polyethylene Terephthalate Upcycling [16] | Landfilling, incineration | Carbonate-interchange deconstruction | Transforms waste to high-value chemicals |

| Graphite Purification [16] | Hydrofluoric acid leaching | Pulsed electrolysis | Eliminates fluoride consumption, sustainable process |

| Polyimide Synthesis [16] | Energy-intensive polymerization | Eco-friendly accelerated method | 94% time reduction, 60% energy reduction, 95% reagent reduction |

| Non-isocyanate Polyurethane [16] | Phosgene-based synthesis | CO₂ and biomass-derived route | Eliminates toxic precursors, uses waste CO₂ |

Global Initiatives and Research Programs

Substantial international efforts are underway to accelerate the development of green chemistry solutions for the SDGs. The "Green Chemistry for Life" project, launched by UNESCO and PhosAgro with IUPAC support, provides a successful model of multi-stakeholder collaboration [6]. This initiative has awarded 41 research grants to young scientists from 29 countries since 2013, with funding exceeding $2.5 million, specifically targeting green chemistry innovations that address multiple SDGs including zero hunger, clean water, climate action, and sustainable consumption [6].

Concurrently, the American Chemical Society has launched the "Campaign for a Sustainable Future" with strategic initiatives designed to position chemistry as a leader in addressing SDG challenges through transformational research and education approaches [11].

Green chemistry provides a robust framework for achieving the UN 2030 Agenda by connecting molecular-level innovations to global sustainability challenges. The strategic mapping of green chemistry principles to specific SDGs enables researchers and drug development professionals to design chemical processes that generate cascading benefits across multiple sustainability dimensions. The experimental protocols and reagent solutions detailed in this technical guide offer practical pathways for implementing SDG-aligned chemistry that reduces hazards, improves efficiency, and creates circular systems.

As the field advances, emerging opportunities in metal-free catalysis, waste valorization, biotechnology, and renewable energy materials will further strengthen chemistry's contribution to sustainable development. By adopting the integrated frameworks presented herein, the chemical research community can accelerate progress toward a sustainable future where molecular design delivers measurable global impact.

The pursuit of Sustainable Development Goal (SDG) 3—ensuring healthy lives and promoting well-being for all—represents a monumental global challenge that intersects critically with environmental sustainability. The pharmaceutical industry faces a dual responsibility: to develop life-saving treatments while minimizing its environmental footprint, which can indirectly harm human health. Green Chemistry provides a transformative framework to reconcile these objectives by designing chemical products and processes that reduce or eliminate the use and generation of hazardous substances [18]. This whitepaper details technical protocols and methodologies for implementing Green Chemistry principles in pharmaceutical research and development, aligning drug discovery with the broader 2030 Agenda for Sustainable Development [19].

The fundamental premise of Green Chemistry is that chemical design should prioritize waste prevention rather than waste cleanup—the first of its 12 principles [20] [21]. When applied to pharmaceutical development, this approach advances SDG 3 by creating safer medicines through less hazardous syntheses [20], while simultaneously supporting SDG targets 3.9 (reducing deaths from hazardous chemicals) [22] and 3.b (supporting research into diseases affecting developing countries) [22]. The integration of these fields represents a critical strategy for achieving equitable, sustainable health outcomes.

Green Chemistry Principles and SDG 3 Synergies

Framework Alignment with Sustainable Development

The 12 Principles of Green Chemistry establish a comprehensive framework for designing pharmaceutical syntheses that minimize environmental impact while maintaining therapeutic efficacy [20]. These principles directly support multiple SDG 3 targets through specific technical applications:

- Principle 3 (Less Hazardous Chemical Syntheses): Directly advances SDG target 3.9 by reducing hazardous chemical releases [22] [20]

- Principle 4 (Designing Safer Chemicals): Creates therapeutic agents with reduced toxicity profiles, supporting SDG 3's broader objective of reducing illness from hazardous chemicals [20]

- Principle 7 (Use of Renewable Feedstocks): Diminishes dependence on finite resources, contributing to sustainable medicine availability (SDG target 3.b) [23] [20]

The following table summarizes the quantitative relationships between Green Chemistry applications and specific SDG 3 indicators:

Table 1: Green Chemistry Applications and Corresponding SDG 3 Impact

| Green Chemistry Principle | Pharmaceutical Application | SDG 3 Target | Measurable Impact |

|---|---|---|---|

| Waste Prevention | Process mass intensity (PMI) optimization | 3.9: Reduce illnesses from hazardous chemicals | Pfizer: 19% waste reduction; 56% productivity improvement [18] |

| Atom Economy | Catalytic reactions vs. stoichiometric | 3.b: Research for diseases in developing countries | AstraZeneca: >75% reduction in CO₂, water, and waste using nickel catalysts [23] |

| Safer Solvents & Auxiliaries | Water/ethanol instead of dichloromethane/benzene | 3.9: Reduce mortality from pollution | Merck: Redesigned sitagliptin synthesis reduced waste, water, and energy use [20] |

| Design for Degradation | Biodegradable pharmaceutical products | 3.4: Reduce premature mortality from NCDs | Prevents persistent environmental pharmaceutical accumulation [20] |

Strategic Integration Pathways

The conceptual relationship between Green Chemistry principles and SDG targets forms an integrated system where medicinal chemistry practices directly support global health objectives:

Graph 1: Green Chemistry and SDG 3 Conceptual Framework. This diagram illustrates the logical pathway connecting Green Chemistry implementation to specific health outcomes that advance SDG 3 targets.

Experimental Protocols for Green Pharmaceutical Development

Catalytic Borylation Using Earth-Abundant Metals

Objective: Implement sustainable metal catalysis to replace precious metals in key carbon-boron bond formation reactions, crucial for synthesizing pharmaceutical intermediates [23].

Background: Traditional borylation reactions rely on palladium catalysts—expensive metals with environmentally damaging extraction processes. Nickel offers a more abundant, cost-effective alternative with significantly lower environmental impact [23].

Protocol:

Reaction Setup:

- In an inert atmosphere glovebox, combine aryl halide (1.0 mmol) and bis(pinacolato)diboron (1.2 mmol) in a Schlenk tube

- Add nickel catalyst (NiCl₂(dppe), 3 mol%) and potassium tert-butoxide (3.0 mmol)

- Charge with 2 mL of 2-MeTHF (a renewable solvent)

Reaction Execution:

- Seal the Schlenk tube and remove from glovebox

- Heat reaction mixture to 80°C with stirring for 12 hours

- Monitor reaction progress by TLC or GC-MS

Workup:

- Cool reaction mixture to room temperature

- Dilute with ethyl acetate (10 mL) and wash with saturated NaCl solution (3 × 5 mL)

- Dry organic layer over MgSO₄, filter, and concentrate under reduced pressure

Purification:

- Purify crude product by flash chromatography (hexanes/ethyl acetate)

- Characterize product by ( ^1H ) NMR, ( ^{13}C ) NMR, and mass spectrometry

Key Research Reagents:

Table 2: Essential Reagents for Nickel-Catalyzed Borylation

| Reagent | Function | Green Chemistry Advantage |

|---|---|---|

| NiCl₂(dppe) | Catalyst | Replaces precious palladium; >75% reduction in CO₂ emissions, freshwater use, and waste generation [23] |

| 2-MeTHF | Solvent | Derived from renewable biomass; preferable to fossil-fuel-derived THF [20] |

| Bis(pinacolato)diboron | Boron source | Enables key molecular diversification for drug discovery [23] |

Late-Stage Functionalization for Molecular Diversification

Objective: Implement late-stage functionalization (LSF) techniques to modify complex molecules efficiently, reducing synthetic steps and resource consumption in drug discovery [23].

Background: LSF introduces structural diversity at the latest possible stage of synthesis, avoiding the need to reconstruct complex intermediates from simple starting materials, significantly improving atom economy [23].

Photocatalytic LSF Protocol:

Reaction Setup:

- Dissolve substrate molecule (0.1 mmol) in acetonitrile (2 mL) in a quartz reaction vessel

- Add photocatalyst (Ir(ppy)₃, 2 mol%) and nitrogen-containing radical precursor (0.2 mmol)

Reaction Execution:

- Degas solution with argon for 10 minutes

- Irradiate with blue LEDs (450 nm) while stirring at room temperature for 6-24 hours

- Monitor reaction by LC-MS until complete consumption of starting material

Workup and Purification:

- Remove solvent under reduced pressure

- Redissolve residue in DCM (3 mL) and filter through a short silica plug

- Concentrate and purify by preparative HPLC

- Characterize functionalized products by NMR and HRMS

Applications: AstraZeneca has utilized LSF to create over 50 different drug-like molecules and developed novel PROTACs (PROteolysis TArgeting Chimeras) for cancer therapeutics in a single synthetic step [23].

Enzyme-Catalyzed Asymmetric Synthesis

Objective: Employ biocatalysts for stereoselective synthesis of pharmaceutical intermediates under mild conditions, replacing traditional synthetic routes requiring hazardous reagents and extreme conditions [23] [20].

Background: Enzymes offer exceptional selectivity and operate under environmentally benign conditions, often consolidating multiple synthetic steps into one-pot processes [23].

Protocol for Ketoreductase-Catalyzed Asymmetric Reduction:

Biocatalytic Reaction:

- Prepare phosphate buffer (50 mM, pH 7.0) containing NADP⁺ (0.2 mM)

- Add prochiral ketone substrate (50 mM) and ketoreductase enzyme (1 mg/mL)

- Include glucose dehydrogenase (0.5 mg/mL) and glucose (100 mM) for cofactor regeneration

Process Execution:

- Incubate at 30°C with shaking at 200 rpm for 8 hours

- Monitor conversion by chiral HPLC

Product Isolation:

- Extract reaction mixture with ethyl acetate (3 × 10 mL)

- Combine organic layers and dry over Na₂SO₄

- Filter and concentrate under reduced pressure

- Determine enantiomeric excess by chiral HPLC

Advantages: Biocatalysis typically achieves in a single synthetic step what can take many steps using traditional methods, with excellent atom economy and minimal waste generation [23].

Quantitative Green Metrics and Analytical Methodologies

Process Mass Intensity (PMI) Assessment

Objective: Quantify the environmental efficiency of synthetic processes using PMI, a key green metric that measures the total mass of materials used per mass of product obtained [23].

Calculation Method: [ \text{PMI} = \frac{\text{Total mass of inputs (kg)}}{\text{Mass of product (kg)}} ]

Implementation Protocol:

Data Collection:

- Record masses of all reagents, solvents, catalysts, and other materials used in synthesis

- Precisely measure mass of isolated active pharmaceutical ingredient (API)

Comparative Analysis:

- Calculate PMI for each synthetic route under consideration

- Use predictive algorithms to identify optimal routes without extensive experimentation [23]

Interpretation:

- Lower PMI values indicate more efficient resource utilization

- Pharmaceutical industry target: Significant reduction from traditional PMI values of 100-200 for API manufacturing

Table 3: Pharmaceutical Industry Green Metric Targets

| Green Metric | Traditional Process | Green Chemistry Target | Industry Example |

|---|---|---|---|

| Process Mass Intensity (PMI) | Often >100 | Significant reduction | AstraZeneca: Novel PMI prediction for route selection [23] |

| E-Factor (kg waste/kg product) | Varies by sector | Minimize approach | Pfizer: 19% waste reduction through green chemistry [18] |

| Solvent Intensity | Major contributor to PMI | Reduction via solvent-free or aqueous systems | Merck: Solvent substitution in sitagliptin synthesis [20] |

| Energy Consumption | High-temperature/pressure requirements | Ambient temperature processes | Photocatalysis and biocatalysis approaches [23] |

Advanced Analytical Monitoring with Process Analytical Technology (PAT)

Objective: Implement real-time analytical monitoring to optimize chemical processes, prevent waste formation, and enhance efficiency [20].

PAT Implementation Framework:

In-line Spectroscopy:

- Install FTIR or Raman probes directly in reaction vessels

- Develop calibration models to quantify reactant consumption and product formation

- Set control limits for critical process parameters

Automated Feedback Control:

- Program automated reagent addition based on real-time analytical data

- Implement temperature control algorithms responsive to reaction progression

- Establish endpoints for reaction quenching based on conversion metrics

Data Integration:

- Correlate process parameters with product quality attributes

- Use machine learning algorithms to identify optimal reaction conditions

- Implement control strategies that minimize resource consumption while maintaining quality

Benefits: PAT enables precise reaction control, reducing excess reagent use, minimizing byproduct formation, and ensuring consistent product quality with reduced reprocessing needs [20].

Sustainable Technology Platforms for Pharmaceutical Manufacturing

Advanced Catalysis Systems

The implementation of innovative catalysis platforms represents a cornerstone of green pharmaceutical manufacturing, directly supporting SDG 3 by making medicine production more sustainable and less polluting.

Photocatalysis Protocol:

Reactor Setup:

- Employ flow chemistry systems with integrated LED light sources

- Use transparent fluoropolymer tubing (0.5-1.0 mm internal diameter) wound around light source

- Set up syringe or piston pumps for precise reagent delivery

Process Optimization:

- Dissolve substrates and photocatalyst in green solvent (e.g., ethyl acetate or 2-MeTHF)

- Optimize flow rate to maximize conversion while minimizing reactor volume

- Determine optimal light intensity and wavelength for specific transformation

Application Example:

- AstraZeneca developed a photocatalyzed reaction that removed several stages from the manufacturing process for a late-stage cancer medicine, leading to more efficient manufacture with less waste [23]

Electrocatalysis Protocol:

Electrochemical Cell Assembly:

- Set up undivided electrochemical cell with graphite electrodes

- Use constant current power supply (typically 5-20 mA/cm²)

- Employ supporting electrolytes compatible with pharmaceutical intermediates (e.g., LiClO₄, NBu₄BF₄)

Reaction Execution:

- Dissolve substrate (0.2 M) and electrolyte (0.1 M) in appropriate solvent

- Apply constant current at room temperature for 2-8 hours

- Monitor charge passed and reaction progress analytically

Advantages:

- Replaces stoichiometric oxidants/reductants with electricity

- Enables unique reaction pathways under mild conditions

- Facilitates selective transformations without protecting groups [23]

Continuous Processing and Miniaturization

High-Throughput Experimentation (HTE) Protocol:

Miniaturized Reaction Screening:

- Use 96-well or 384-well microtiter plates for reaction screening

- Employ liquid handling robots for precise reagent addition (1-10 μL volumes)

- Implement parallel synthesis under varied conditions (catalyst, solvent, temperature)

Rapid Reaction Optimization:

- Design statistical experiments (DoE) to efficiently explore parameter space

- Analyze results using HPLC-MS with automated sample injection

- Identify optimal conditions with minimal material consumption (1 mg scale) [23]

Advantages:

- AstraZeneca in collaboration with Stockholm University performed thousands of reactions using as little as 1mg of starting material, exploring a much larger range of drug-like molecules compared to standard techniques [23]

The methodologies and protocols detailed in this whitepaper demonstrate that Green Chemistry provides the necessary technical foundation for advancing SDG 3 while minimizing environmental impact. The pharmaceutical industry's adoption of these approaches represents a critical convergence of therapeutic innovation and environmental responsibility. The experimental workflows, metrics, and technologies outlined enable researchers to design pharmaceutical development programs that simultaneously address human health needs and environmental sustainability.

Future progress will require continued interdisciplinary collaboration, education in Green Chemistry principles, and policy frameworks that incentivize sustainable medicinal chemistry practices. As the industry moves toward these integrated approaches, Green Chemistry will increasingly become the standard methodology for pharmaceutical development, ultimately creating a healthcare paradigm that promotes human health without compromising planetary health. The implementation of these strategies positions the pharmaceutical industry as a key contributor to achieving the 2030 Agenda for Sustainable Development, particularly SDG 3's vision of health and well-being for all.

The United Nations 2030 Agenda for Sustainable Development represents a universal call to action to end poverty, protect the planet, and ensure peace and prosperity for all. At the intersection of environmental protection and human well-being lies Sustainable Development Goal 6 (SDG 6), which commits the global community to "ensure availability and sustainable management of water and sanitation for all" [24]. A critical component of this goal—Target 6.3—specifically aims to "improve water quality by reducing pollution, eliminating dumping and minimizing release of hazardous chemicals and materials, halving the proportion of untreated wastewater, and substantially increasing recycling and safe reuse globally" [24].

Green chemistry, defined as "the design of chemical products and processes that reduce or eliminate the use or generation of hazardous substances," provides the foundational methodology to achieve this target [1]. Unlike pollution cleanup approaches, green chemistry employs inherent pollution prevention at the molecular level, designing chemical processes that minimize the creation of hazardous substances from the outset [1]. For researchers and drug development professionals, integrating green chemistry principles into water management strategies represents a transformative opportunity to address both water pollution at its source and the broader challenges of sustainable development.

The Water Challenge and Chemical Pollution

Current global water statistics underscore the urgency of addressing chemical pollution. Despite progress, 2.2 billion people still lacked safely managed drinking water in 2024, while 3.4 billion people lacked safely managed sanitation services [24]. Water pollution from hazardous chemicals poses significant challenges to human health and aquatic ecosystems, with only approximately 40% of surface waters globally in good chemical status [25].

Climate change intensifies these challenges by altering precipitation patterns and increasing water scarcity. The number of people living in water-scarce areas is projected to rise from 1.9 billion to approximately 3 billion by 2050 [25]. These constraints necessitate more efficient, resilient, and sustainable approaches to water management in pharmaceutical development and industrial chemical processes.

Green Chemistry vs. Sustainable Chemistry in Water Management

While the terms are often used interchangeably, important distinctions exist between green and sustainable chemistry in the context of water management:

- Green Chemistry: Primarily focuses on minimizing environmental impact by reducing waste, energy consumption, and toxicity in chemical processes [25]. It provides the molecular-level design framework for pollution prevention in water systems.

- Sustainable Chemistry: Adopts a broader perspective, seeking solutions that are not only environmentally benign but also socially equitable and economically viable [25]. It considers the entire life cycle of chemical processes and their role in comprehensive water management systems.

For drug development professionals, this distinction is crucial when designing water treatment strategies that are both technically effective and scalable within economic and infrastructure constraints.

Green Chemistry Principles for Hazard Reduction

The Twelve Principles of Green Chemistry, established by Anastas and Warner, provide a comprehensive framework for designing chemical processes that minimize environmental impact [1] [26]. Several principles offer specific guidance for reducing the release of hazardous chemicals into water systems:

Directly Relevant Principles for Water Protection

Table 1: Key Green Chemistry Principles for Minimizing Hazardous Chemical Release

| Principle | Application to Water Protection | Research Approach |

|---|---|---|

| #3: Design Less Hazardous Chemical Syntheses | Design synthetic pathways that use and generate substances with minimal toxicity to aquatic life and human health [1]. | Develop alternative catalytic pathways that avoid heavy metal catalysts and persistent organic pollutants. |

| #4: Design Safer Chemicals | Create pharmaceutical products and intermediates that maintain therapeutic efficacy while being readily degradable to innocuous substances [1]. | Design active pharmaceutical ingredients (APIs) with hydrolyzable functional groups that break down in treatment systems. |

| #5: Use Safer Solvents and Reaction Conditions | Replace hazardous organic solvents (chlorinated, aromatic) with safer alternatives to prevent groundwater contamination [1]. | Utilize water-based reaction media, ionic liquids, or bio-based solvents with lower aquatic toxicity. |

| #10: Design for Degradation | Create chemicals that break down into harmless substances after use rather than persisting in water systems [1]. | Incorporate molecular "break points" that facilitate hydrolysis or biodegradation in environmental conditions. |

| #12: Minimize Accident Potential | Select chemical forms and process conditions to reduce potential for spills, explosions, or environmental releases [1]. | Develop solid-supported reagents, continuous flow processes, and inherently safer process designs. |

Quantitative Metrics for Assessing Chemical Impact

Measuring the environmental impact of chemical processes is essential for evaluating progress toward SDG 6.3. Several well-established metrics enable researchers to quantify and compare the "greenness" of alternative processes [26] [27].

Core Mass Efficiency Metrics

Table 2: Quantitative Green Chemistry Metrics for Process Evaluation

| Metric | Calculation | Application | Ideal Value |

|---|---|---|---|

| E-Factor (Environmental Factor) | Total waste (kg) / Product (kg) [27] | Measures waste generation efficiency across industry sectors; lower values indicate less waste [27]. | Approaches 0 |

| Atom Economy | (MW of Product / Σ MW of Reactants) × 100% [27] | Theoretical measure of efficient atom incorporation; higher values indicate less inherent waste [26]. | 100% |

| Reaction Mass Efficiency (RME) | (Mass of Product / Σ Mass of Reactants) × 100% [26] | Experimental measure incorporating yield, stoichiometry, and solvent use [26]. | 100% |

| Process Mass Intensity (PMI) | Total mass in process (kg) / Mass of product (kg) [27] | Comprehensive measure of resource efficiency including all inputs; related to E-Factor (PMI = E-Factor + 1) [27]. | Approaches 1 |

These metrics enable drug development professionals to set benchmarks and track improvements in process sustainability. For context, typical E-Factor values vary widely across industry sectors, with pharmaceutical manufacturing typically ranging from 25 to >100, significantly higher than bulk chemicals (<1-5) [27]. This highlights substantial opportunity for improvement in pharmaceutical production through green chemistry innovation.

Experimental Protocols for Hazard Reduction

Green Synthesis of Active Pharmaceutical Ingredients (APIs)

Objective: Implement green chemistry principles to synthesize pharmaceutical compounds while minimizing generation of hazardous waste that could impact water quality.

Methodology:

Catalytic System Design:

Solvent Selection Guide:

- Apply SANESS (Solvent Alternative Guide for Enhanced Environmental and Safety Standards) tool for solvent substitution

- Prioritize water, ethanol, ethyl acetate, and 2-methyltetrahydrofuran over hazardous alternatives

- Implement solvent recovery and recycling systems with >90% recovery efficiency targets

Process Analytical Technology (PAT):

- Integrate in-line spectroscopy (FTIR, Raman) for real-time reaction monitoring [1]

- Implement feedback control systems to optimize reaction parameters and minimize byproduct formation

- Utilize automated continuous extraction systems to reduce solvent consumption in workup steps

Assessment:

- Calculate E-Factor and PMI for both traditional and green synthesis routes

- Conduct aquatic toxicity testing of process effluents using Daphnia magna or algal bioassays

- Perform life cycle assessment (LCA) to quantify overall environmental impact reduction

Advanced Oxidation Processes for Micropollutant Destruction

Objective: Develop efficient treatment methods for pharmaceutical residues and persistent organic pollutants in wastewater.

Methodology:

Catalyst Development:

- Synthesize heterogeneous Fenton catalysts using iron-supported mesoporous materials

- Develop TiO₂-based photocatalysts doped with nitrogen or sulfur for visible light activation

- Create peroxymonosulfate-activating catalysts for sulfate radical-based oxidation

Reactor Configuration:

- Design falling film reactors for enhanced gas-liquid mass transfer

- Implement LED-based photoreactors with specific wavelength emission matched to catalyst bandgap

- Utilize continuous-flow packed-bed reactors for heterogeneous catalytic systems

Process Optimization:

- Determine optimal oxidant dosage using response surface methodology (RSM)

- Identify key operating parameters (pH, catalyst loading, hydraulic retention time) through factorial design

- Establish correlation between structural attributes of pollutants and their degradation kinetics

Analysis:

- Monitor pollutant concentration using LC-MS/MS with detection limits <10 ng/L

- Quantify transformation products to ensure complete mineralization

- Assess biodegradability enhancement of treated effluent using BOD₅/COD ratio

- Evaluate ecotoxicity reduction using aquatic bioassays

Diagram 1: Advanced oxidation process workflow for pharmaceutical pollutant degradation

The Researcher's Toolkit: Materials and Methods

Research Reagent Solutions for Green Water Treatment

Table 3: Essential Materials for Green Chemistry Water Research

| Research Reagent | Function | Green Chemistry Principle |

|---|---|---|

| Iron-Based Fenton Catalysts | Generate hydroxyl radicals for pollutant degradation without secondary pollution [25]. | #3: Less Hazardous Chemical Syntheses |

| Molecularly Imprinted Polymers | Selective recognition and removal of specific pharmaceutical residues from water [25]. | #5: Safer Solvents & Auxiliaries |

| Bio-Based Adsorbents (chitosan, cellulose) | Renewable materials for heavy metal and organic pollutant adsorption [25]. | #7: Renewable Feedstocks |

| Nanocatalysts (doped TiO₂, ZnO) | Photocatalytic degradation of persistent organic pollutants under visible light [25]. | #9: Catalysis |

| Ionic Liquids | Green extraction solvents for preconcentration and recovery of contaminants from water [25]. | #6: Energy Efficiency |

| Enzymatic Treatment Systems (laccase, peroxidase) | Biocatalytic degradation of pharmaceuticals under mild conditions [25]. | #10: Design for Degradation |

| Membrane Materials (graphene oxide, biomimetic) | Energy-efficient separation with fouling resistance for water reuse [25]. | #12: Inherently Safer Chemistry |

Implementation Framework and Future Directions

Implementing green chemistry solutions for SDG 6.3 requires systematic approaches that integrate technological innovation with policy and collaborative frameworks. The following strategic priorities emerge from current research:

Interdisciplinary Collaboration Models

Addressing complex water challenges requires integration of green and sustainable chemistry with engineering, toxicology, and policy disciplines [25]. Effective models include:

- Academic-Industry Partnerships: Accelerate translation of laboratory discoveries to scalable water treatment technologies

- Living Labs: Create science-policy-stakeholder interfaces for testing innovations in real-world contexts [25]

- Open Innovation Platforms: Share data, methodologies, and best practices across institutional boundaries

Circular Economy Integration

Transitioning from linear "take-make-dispose" models to circular approaches represents a paradigm shift in water and chemical management:

- Water Reuse and Recycling: Develop closed-loop systems for industrial process water, particularly in pharmaceutical manufacturing

- Resource Recovery: Extract and valorize nutrients, energy, and materials from wastewater streams [25]

- Molecular Recycling: Design chemical products for disassembly and recovery of valuable components

Policy and Regulatory Alignment

Green chemistry innovations require supportive policy frameworks to achieve widespread adoption:

- Green Chemistry Education: Integrate sustainable molecular design principles into chemistry curricula [11] [26]

- Economic Incentives: Develop preferential procurement policies for chemicals and processes with reduced aquatic toxicity

- International Standards: Harmonize metrics and reporting frameworks for tracking progress toward SDG 6.3 targets

Green chemistry provides essential tools and methodologies for achieving Target 6.3 of Sustainable Development Goal 6 by addressing the release of hazardous chemicals at the molecular design stage. Through the application of the Twelve Principles, utilization of quantitative metrics, and development of innovative treatment technologies, researchers and drug development professionals can significantly contribute to protecting global water resources. The integration of advanced materials, catalytic systems, and circular economy principles represents a promising pathway toward sustainable water management that aligns with the broader objectives of the UN 2030 Agenda. As climate change intensifies water challenges, the role of green chemistry in developing resilient, adaptive, and equitable solutions becomes increasingly critical for ensuring clean water and sanitation for all.

The 2030 Agenda for Sustainable Development represents a universal plan of action to shift the world onto a sustainable and resilient path, balancing economic, social, and environmental dimensions [19]. Sustainable Development Goal 9 (SDG 9) specifically calls for building resilient infrastructure, promoting inclusive and sustainable industrialization, and fostering innovation [19]. Within this framework, green chemistry emerges as a critical scientific discipline that redefines the role of the chemical industry and allied sectors, including pharmaceutical development, in achieving these targets. Green chemistry provides the foundational principles and methodologies to redesign chemical processes and products, thereby supporting the core aspirations of SDG 9 by enabling more efficient, less wasteful, and inherently safer industrial practices [28] [11] [5].

This technical guide explores the specific mechanisms through which green chemistry supports the implementation of the 2030 Agenda, with a focus on SDG 9. It provides a detailed examination of integrative frameworks, computational methodologies, and experimental protocols that translate the principles of green chemistry into tangible advancements in sustainable industrial innovation.

Integrative Frameworks for Sustainable Chemistry

The transition from a traditional linear model of chemical production to a sustainable one requires the synergistic integration of several complementary frameworks. The conventional "take-make-waste" model poses significant socio-environmental challenges, creating an urgent need for a paradigm shift [28]. Operating in silos, individual approaches like green chemistry, circular chemistry, and Safe and Sustainable-by-Design (SSbD) yield suboptimal results. A unified framework is necessary to overcome existing barriers and significantly enhance the chemical industry's sustainability profile [28].

The following diagram illustrates the synergistic relationship between these core frameworks in achieving sustainable chemistry for SDG 9.

This integrated approach directly contributes to SDG 9 targets by:

- Retrofitting and Improving Industrial Infrastructure: Upgrading existing production facilities to be more sustainable, efficient, and less polluting [11].

- Enabling Resource Efficiency: Promoting the use of renewable feedstocks and waste recycling, which enhances resource security and reduces environmental impact, crucial for resilient infrastructure [28] [11].

- Fostering Innovation: Driving the development of novel, safer materials and chemical processes that are inherently less hazardous and generate less waste [29] [11].

Computational and Data-Driven Methodologies

The design of sustainable chemical processes is increasingly reliant on computational tools and data science, which allow for the in silico optimization of reactions and materials before resource-intensive laboratory work begins. These tools are particularly vital in pharmaceutical research and development, where they can significantly reduce the environmental footprint of drug discovery and manufacturing [30].

The Data Science and Modeling for Green Chemistry award, administered by the ACS Green Chemistry Institute, highlights the critical importance of these tools in guiding the design of sustainable chemical processes that demonstrate compelling environmental, safety, and efficiency improvements [30]. The workflow for using these computational tools is methodical and iterative, as shown below.

Key Computational Tools and Their Functions

The selection of computational tools is based on their ability to address specific challenges in green chemistry. The table below summarizes the core functions and selection criteria for these tools, which are essential for reducing the need for extensive laboratory experimentation [30].

Table 1: Key Computational Tools for Green Chemistry Research and Development

| Tool Category | Primary Function | Key Assessment Metrics | Application in Pharmaceutical R&D |

|---|---|---|---|

| AI/Machine Learning Platforms | Predict greener reagents, catalysts, and reaction outcomes. | Versatility, applicability across different reaction types. | Wide application across pharmaceutical industry for reaction optimization [30]. |

| Toxicity Prediction Software | Assess safety and toxicity profiles of chemicals and intermediates. | Validation and reliability against experimental data. | Design of less hazardous compounds and identification of safer alternatives [30]. |

| Process Simulation Software | Model and optimize entire manufacturing processes for efficiency. | Efficiency and cost-effectiveness in resource utilization. | Reduction of Process Mass Intensity (PMI), energy, and water usage [30]. |

| Life Cycle Assessment (LCA) Tools | Quantify environmental impacts of a product or process across its life cycle. | Comprehensive environmental impact assessment. | Evaluation of carbon emissions and resource depletion from feedstock to disposal [5]. |

The efficacy of these tools is evaluated against stringent criteria, including innovation, environmental impact reduction, cost-effectiveness, safety prediction accuracy, versatility, and user-friendliness [30]. Their integration into the R&D workflow is fundamental for advancing the targets of SDG 9, as they directly enhance innovation and enable the development of more sustainable industrial infrastructure.

Experimental Protocols for Assessing Material Sustainability

Translating computational designs into tangible outcomes requires robust experimental validation. The following section provides a detailed, transferable protocol for investigating material degradation—a critical aspect of Principle 10: Design for Degradation of Green Chemistry. This protocol is adapted from an inquiry-based learning study conducted with secondary school students, demonstrating how fundamental principles can be applied in practical research settings [31].

Methodology for Long-Term Material Degradation Inquiry

Objective: To quantitatively and qualitatively assess the degradation behavior of common materials (paper, cardboard, plastic, metal) under various environmental conditions over an extended period (e.g., 100 days) [31].

1. Hypothesis Development:

- Students/researchers hypothesize that different materials will exhibit significantly different degradation rates based on their chemical composition and structure, with biodegradable materials like paper showing more rapid changes than synthetic polymers or metals [31].

2. Experimental Design and Setup:

- Materials: Identical samples of paper, cardboard, plastic, and metal.

- Site Selection: An outdoor location exposed to natural environmental conditions.

- Experimental Variables: The study leverages natural environmental factors that drive degradation [31]:

- Photodegradation: Exposure to solar radiation.

- Thermal Degradation: Exposure to diurnal temperature fluctuations.

- Hydrolytic Degradation: Exposure to humidity and rain.

- Biodegradation: Potential for fungal/bacterial growth.

- Chemical Degradation/Corrosion: Reaction with environmental chemicals.

3. Data Collection and Monitoring:

- Schedule: Regular, systematic observations (e.g., weekly).

- Qualitative Data: Photographic documentation and written descriptions of physical changes (e.g., color fading, brittleness, rust formation, surface fouling) [31].

- Quantitative Data: Measurement of mass loss and dimensional changes.

4. Data Analysis and Modeling:

- Data Integration: Correlate observed degradation with weather data (sunlight, rainfall, temperature).

- Explanatory Models: Develop models that explain the degradation processes of each material, considering the interplay of environmental factors and material properties [31].

Key Findings and Green Chemistry Principles

The execution of this protocol led to several key findings that implicitly reflect the principles of green chemistry [31]:

- Finding: After 100 days, paper and cardboard showed significant degradation, while plastic and metal exhibited minimal visual and mass change.