Green Chromatography: Enhancing Peak Resolution in Residual Solvent Analysis for Sustainable Pharma

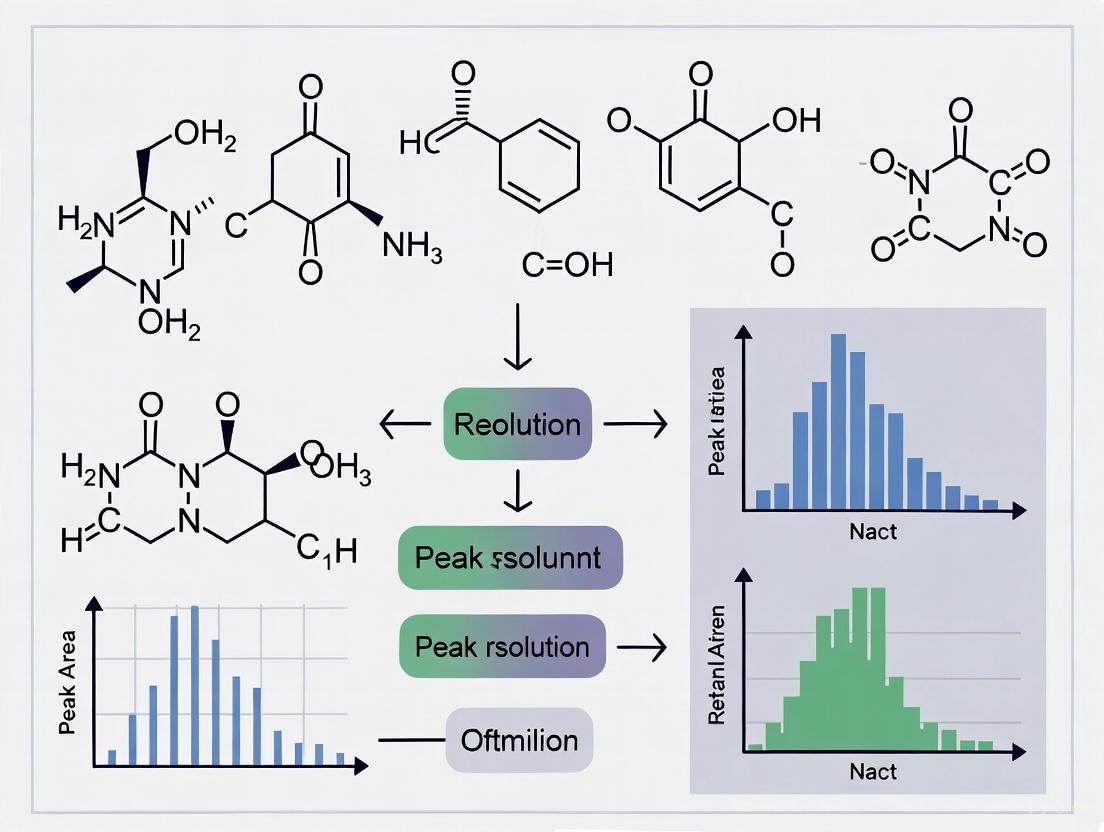

This article addresses the critical challenge of improving chromatographic peak resolution while simultaneously adopting greener, more sustainable solvents in residual solvent analysis (RSA).

Green Chromatography: Enhancing Peak Resolution in Residual Solvent Analysis for Sustainable Pharma

Abstract

This article addresses the critical challenge of improving chromatographic peak resolution while simultaneously adopting greener, more sustainable solvents in residual solvent analysis (RSA). Aimed at researchers, scientists, and drug development professionals, it explores the foundational principles of RSA governed by ICH Q3C and USP <467> guidelines. It then provides a methodological framework for integrating green solvents like methanol and sustainable chromatographic practices, supported by case studies. The content further offers practical troubleshooting strategies for common resolution issues and details robust validation protocols to ensure method compliance, accuracy, and comparability with traditional techniques. The synthesis of these areas provides a actionable path toward more efficient, accurate, and environmentally responsible pharmaceutical quality control.

Fundamentals of Residual Solvent Analysis and the Green Solvent Imperative

Residual solvents are organic volatile chemicals used or produced during the manufacture of drug substances, excipients, or drug products. Since these solvents provide no therapeutic benefit and can pose significant health risks, global regulatory bodies have established strict guidelines for their control. The International Council for Harmonisation (ICH) Q3C guideline and the United States Pharmacopeia (USP) General Chapter <467> provide the foundational framework for classifying residual solvents and setting allowable limits. This technical support center article explores these classifications within the context of research aimed at improving peak resolution in residual solvent analysis, particularly when investigating greener solvent alternatives.

Solvent Classifications and Regulatory Guidelines

Understanding the Regulatory Framework

ICH Q3C and USP <467> provide a harmonized approach to classifying residual solvents based on their toxicity and risk to human health. The core difference lies in their scope: while ICH Q3C applies to new drug products, USP <467> applies the same requirements to all new and existing drug products [1]. These regulations oblige manufacturers to ensure pharmaceuticals are free from toxicologically significant levels of volatile organic compounds, typically using headspace gas chromatography (GC) often coupled with mass spectrometry (GC-MS) for identification and quantification [1].

Solvent Classification System

The guidelines categorize solvents into three classes based on toxicity [1] [2]:

Class 1: Solvents to Be Avoided Known human carcinogens, strongly suspected human carcinogens, and environmental hazards. Their use should be avoided in pharmaceutical manufacturing.

Class 2: Solvents to Be Limited Non-genotoxic animal carcinogens or possible causative agents of other irreversible toxicity such as neurotoxicity or teratogenicity. They may also include solvents suspected of other significant but reversible toxicities.

Class 3: Solvents with Low Toxic Potential Solvents with low toxic potential to humans; no health-based exposure limit is needed. Class 3 solvents have Permitted Daily Exposures (PDEs) of 50 mg or more per day.

Table 1: Class 1 Residual Solvents (Selected Examples)

| Solvent | PDE (mg/day) | Concentration Limit (ppm) |

|---|---|---|

| Benzene | - | 2 [1] |

| Carbon tetrachloride | - | 4 [1] |

| 1,2-Dichloroethane | - | 5 [1] |

| 1,1-Dichloroethene | - | 8 [1] |

Table 2: Class 2 Residual Solvents (Selected Examples)

| Solvent | PDE (mg/day) | Concentration Limit (ppm) |

|---|---|---|

| Acetonitrile | 4.1 | 410 [1] |

| Chloroform | 0.6 | 60 [1] |

| Dichloromethane | 6.0 | 600 [1] |

| Methanol | 30.0 | 3000 [1] |

| Toluene | 8.9 | 890 [1] |

For Class 3 solvents, a nonspecific method like loss on drying (LOD) may be used if only Class 3 solvents are present and the LOD is ≤ 0.5% [3]. If the LOD is greater than 0.5%, the Class 3 solvents should be quantified [3].

Troubleshooting Guides and FAQs

Frequently Asked Questions

1. What is the practical difference between ICH Q3C and USP <467>? While the limits for solvents are harmonized, the key difference is that USP <467> applies to all drug products (new and existing), whereas ICH Q3C applies only to new drug products [1]. For compliance in the U.S. market, USP <467> is mandatory for relevant submissions [2].

2. My product exceeds the Option 1 limit for a Class 2 solvent. Does it automatically fail? Not necessarily. You can use Option 2 - Summation of Components [3]. If the total daily exposure to the solvent from all components in the product formulation is below the Permitted Daily Exposure (PDE), the product still conforms to the requirements, even if individual components exceed the Option 1 concentration limit (ppm) [3].

3. When can I use Loss on Drying (LOD) instead of GC? LOD can be used as a non-specific method only if you have confirmed that only Class 3 solvents are present and the LOD result is ≤ 0.5% [3]. If Class 1 or Class 2 solvents are potentially present, or if the LOD is >0.5%, you must use a chromatographic method like GC to identify and quantify the specific residual solvents [3].

4. What if I use a solvent not listed in ICH Q3C or USP <467>? If solvents other than those included in the guidance are used, the manufacturer is required to establish a suitable residual solvent testing method and determine an acceptable PDE for that solvent based on toxicity data [4].

Troubleshooting Common Analytical Issues

Problem: Poor Peak Resolution for Solvents in a Complex Mixture.

- Potential Cause: The chromatographic method (column or temperature program) is not optimal for separating the specific solvents in your sample, especially when researching alternative green solvent mixtures.

- Solution: Consider switching the chromatographic column. USP <467> lists alternative columns such as a 6% cyanopropylphenyl/94% dimethyl polysiloxane phase (e.g., USP G43) or a polyethylene glycol phase (e.g., USP G16) [3]. Adjust the temperature program ramp rate to improve separation between closely eluting peaks.

Problem: Inconsistent Results During Method Transfer to a New Headspace Autosampler.

- Potential Cause: Inconsistent control of headspace parameters can lead to poor precision.

- Solution: Meticulously control and document headspace conditions. Standard parameters per USP <467> procedures include [3]:

- Equilibration Temperature: 80°C - 105°C

- Equilibration Time: 45 - 60 minutes

- Transfer Line Temperature: 85°C - 110°C

- Pressurization Time: ≥ 60 seconds

Problem: Insensitive Detection of Low ppm Level Class 1 Solvents.

- Potential Cause: The standard Flame Ionization Detector (FID) method may lack the required sensitivity and specificity for trace-level confirmation.

- Solution: Employ a Gas Chromatograph-Mass Spectrometer (GC-MS) for confirmatory testing [1] [2]. MS detection provides superior sensitivity and confirmation via mass spectral identification, which is crucial for toxic Class 1 solvents.

Experimental Protocols and Workflows

Standard Analytical Procedure for Residual Solvents

The following protocol is a synthesis of standard methods for residual solvent analysis via Headspace Gas Chromatography (HS-GC), which is the benchmark technique in this field [1] [2].

1. Sample Preparation:

- Water-Soluble Articles: Dissolve about 250 mg of the test material in water in a 25 mL volumetric flask. Transfer 5.0 mL of this solution to a headspace vial containing 1.0 mL of water [3].

- Water-Insoluble Articles: Dissolve about 500 mg of the test material in N,N-Dimethylformamide (DMF) in a 10 mL volumetric flask. Transfer 1.0 mL of this solution to a headspace vial containing 5.0 mL of water [3].

- Internal Standard: Use an appropriate internal standard (e.g., Limonene has been used in similar applications) to improve quantitative accuracy [5].

2. Instrumental Parameters (Example for a Screening Procedure - Procedure A):

- GC System: Equipped with Flame Ionization Detector (FID) or Mass Spectrometer (MS).

- Carrier Gas: Helium or Hydrogen. Hydrogen can be a viable alternative, produced via generators, and helps mitigate helium supply shortages [5].

- Column: 6% cyanopropylphenyl-94%-dimethyl polysiloxane (e.g., USP G43), 30 m x 0.32 mm or 0.53 mm, 1.8 μm or 3.0 μm film thickness [3].

- Temperature Program: 40°C for 20 minutes, then ramp at 10°C/minute to 240°C, hold for 20 minutes [3].

- Headspace Conditions: Equilibration at 80°C for 60 minutes, transfer line at 85°C, pressurization for ≥60 seconds, injection volume of 1 mL [3].

3. System Suitability and Calibration:

- Linearity: Prepare a series of standard solutions at a minimum of 5 concentration levels. The correlation coefficient (r²) should typically be >0.98 [5].

- Precision: System precision should be determined, for example, using the Horwitz equation to calculate an acceptable Horwitz Ratio (Hr) [5].

Logical Workflow for Residual Solvent Control

The following diagram outlines the decision-making process for controlling residual solvents as per regulatory guidelines, a critical roadmap for planning analyses.

Residual Solvent Control Workflow

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Research Reagent Solutions for Residual Solvent Analysis

| Item | Function/Benefit | Application Note |

|---|---|---|

| Headspace Autosampler | Automates the introduction of the vapor phase above a sample into the GC, improving reproducibility and throughput for volatile analysis [1]. | Valve-and-loop systems offer precise pneumatic control and direct column connection for robust performance [1]. |

| GC with FID/MS Detection | GC separates the volatile components; FID provides universal detection for hydrocarbons, while MS provides definitive identification [1] [2]. | GC-MS is often used for confirmatory testing and provides superior sensitivity for toxic Class 1 solvents [1] [2]. |

| Cyanopropylphenyl / Dimethyl Polysiloxane Column | A mid-polarity stationary phase (e.g., USP G43) recommended in USP <467> for separating a wide range of residual solvents [3]. | This phase is specified for USP <467> Procedure A and C, providing an excellent starting method for most screening assays [3]. |

| Headspace Grade Solvents | High-purity solvents (Water, DMSO, DMF, DMAC) with minimal volatile impurities to prevent background interference in trace analysis [1]. | Essential for preparing sample solutions and standards, especially for analytes at low ppm levels. Critical for insoluble APIs [1]. |

| Hydrogen Generator | Provides a reliable, renewable, and cost-effective source of carrier gas for GC, mitigating the global helium supply shortages [5]. | Using hydrogen as a carrier gas has been successfully validated for residual solvent analysis, providing excellent linearity and precision [5]. |

The Critical Role of Peak Resolution in Accurate Quantification and Patient Safety

FAQs: Peak Resolution Fundamentals

What is chromatographic peak resolution and why is it critical? Chromatographic resolution (Rs) is a quantitative measure of the separation between two adjacent peaks in a chromatogram. The general resolution equation is defined as Rs = Δs / wav, where Δs is the spacing between the apex of two signals and wav is their average baseline width [6]. Baseline resolution (where the detector trace returns to baseline between peaks) is the goal for every analysis, as it ensures accurate identification and quantification of all analytes in a sample [7]. For Gaussian-shaped peaks, satisfactory quantitation is achieved when Rs ≥ 1.0, while near-complete separation requiring Rs ≥ 1.5 [6].

How does poor peak resolution directly impact patient safety? In pharmaceutical analysis, poor resolution can lead to false quantification of active pharmaceutical ingredients (APIs) and their impurities or degradation products. If residual solvents or toxic impurities are not properly separated and quantified, they may exceed safe limits in final drug products [8]. Proper resolution is particularly crucial for residual solvent analysis, as these solvents (classified by ICH into three categories based on toxicity) can pose significant health risks if not controlled within established safety limits [9].

What resolution value indicates adequate separation for accurate quantification? The required resolution depends on the application and acceptable error margins. The relationship between resolution and quantification error is summarized in the table below [6]:

| Resolution (Rs) | Peak Overlap | Maximum Quantification Error | Pure Compound Recovery |

|---|---|---|---|

| 0.25 | 99.9% | 99.9% | 0.1% |

| 0.50 | 93.7% | 93.7% | 6.3% |

| 0.75 | 80.9% | 80.9% | 19.1% |

| 1.00 | 2.2% | 50.0% | 97.8% |

| 1.25 | 0.5% | 12.5% | 99.5% |

| 1.50 | 0.1% | 2.3% | 99.9% |

For most pharmaceutical applications, a resolution of 1.5 or higher is targeted to ensure accurate quantification with minimal error [6].

Troubleshooting Guide: Loss of Peak Resolution

Problem: Decreased separation between peaks

Symptoms: Peaks that were previously resolved now show increased overlap; retention times have shifted closer together.

Possible Causes and Solutions:

- Change in column temperature: Verify and stabilize the column temperature according to method specifications [10].

- Column degradation or contamination: Replace the column or perform recommended cleaning procedures [7] [10].

- Mobile phase composition changes: Prepare fresh mobile phase and verify composition, pH, and buffer strength [7].

- Incorrect column stationary phase: Verify that the installed column matches the method requirements [11].

Problem: Increased peak width

Symptoms: Peaks appear broader than expected; overall chromatographic efficiency has decreased.

Possible Causes and Solutions:

- Sample overloading: Dilute the sample or reduce injection volume [7] [10].

- Column contamination: Bake out the column (for GC) or clean according to manufacturer recommendations [10].

- Extra-column band broadening: Use appropriate injector settings, narrow-bore tubing, and low-dead-volume fittings [12].

- Flow rate too high: Optimize flow rate to find the balance between resolution and analysis time [7].

- Data acquisition rate too low: Ensure sufficient data points are collected (minimum 20, ideally 30-40 points per peak) [7].

Systematic approach to troubleshooting: When resolution problems occur, adopt a systematic approach by changing only one parameter at a time while keeping others consistent to determine the effectiveness of each step [7]. Begin with simple checks of mobile phase composition and column temperature before progressing to more complex adjustments of stationary phase or instrument components.

Experimental Protocols for Improving Resolution

Method 1: Mobile Phase Optimization for Improved Selectivity

Principle: Alter the relative retention (α) of compounds by changing the mobile phase composition [11].

Procedure:

- Begin with initial separation using standard conditions (e.g., 50% acetonitrile/water for reversed-phase HPLC).

- To change selectivity, replace acetonitrile with methanol at equivalent solvent strength (57% methanol for 50% acetonitrile) [11].

- If unsuccessful, try tetrahydrofuran as organic modifier (35% THF for 50% acetonitrile) [11].

- For ionizable compounds, adjust mobile phase pH in 0.5 unit increments within the column's safe pH range.

- Evaluate buffer concentration (typically 10-50 mM) to control ionic interactions.

Expected Results: Changing organic modifier can produce significant peak spacing changes, potentially resolving co-eluted compounds with different chemical properties [11].

Method 2: Column Efficiency Enhancement

Principle: Improve resolution by increasing column plate number (N) to produce sharper peaks [11].

Procedure:

- Particle size reduction: Replace column with smaller particle size equivalent (e.g., from 5μm to 2.7μm superficially porous particles) [11].

- Column length adjustment: Increase column length (e.g., from 100mm to 200mm) while proportionally adjusting flow rate to maintain separation time [11].

- Temperature optimization: Elevate column temperature in 10°C increments (typically 40-60°C for small molecules; 60-90°C for large molecules) to improve efficiency [11].

- Flow rate optimization: Test flow rates from 0.8-1.5 mL/min for standard bore columns to find optimum efficiency.

Expected Results: Using smaller particles can increase resolution from 0.8 to 1.25 for challenging peak pairs, as demonstrated with benzodiazepine separations [11].

Research Reagent Solutions for Residual Solvent Analysis

The following table details essential materials and their functions for developing robust residual solvent methods with optimal peak resolution:

| Reagent/Material | Function in Analysis | Green Alternative Considerations |

|---|---|---|

| DB-624 GC Column (30m × 0.53mm, 3μm) | Stationary phase for separation of volatile solvents; provides optimal resolution of solvent mixtures [9] | - |

| N-Methyl-2-pyrrolidinone (NMP) | High-boiling diluent for headspace analysis; enables detection of various solvent classes [9] | Assess potential for safer solvent substitutes |

| Piperazine | Additive to NMP (1%) to improve peak shape for amines [9] | Evaluate green chemistry principles |

| Reference Standards | Methanol, ethanol, acetone, isopropyl alcohol, etc. for method calibration and qualification [9] | Source from sustainable suppliers |

| Buffer Solutions | Control pH in liquid chromatography for reproducible retention times [7] | - |

Implementation Note: When developing methods for residual solvent analysis, proper column selection is crucial. The DB-624 column has demonstrated resolution >2.0 between solvent peaks in paclitaxel analysis, which is essential for accurate quantification of Class 1 and Class 2 solvents [9].

Advanced Techniques: Peak Purity Assessment

Principles and Applications: Peak purity assessment is critical in pharmaceutical analysis to ensure analytical methods can distinguish APIs from impurities and degradants. Photodiode array (PDA)-facilitated peak purity assessment is the most common approach, which examines changes in the UV absorbance spectrum throughout the peak to detect coeluted compounds with different UV spectra [13].

Procedure for PDA-Based Peak Purity Assessment:

- Acquire UV spectra across the peak (front, apex, and tail).

- Perform baseline correction by subtracting interpolated baseline spectra.

- Convert spectra to vectors in n-dimensional space and minimize vector lengths using least-squares regression.

- Calculate purity angle (weighted average of all calculated angles between spectra) and purity threshold (angle accounting for solvent and noise contributions).

- A peak is considered spectrally pure when the purity angle is less than the purity threshold [13].

Limitations and Complementary Techniques: PDA-based peak purity assessment has limitations, including potential false negatives when coeluted impurities have similar UV spectra or poor UV responses. Alternative techniques include [13]:

- Mass spectrometry-facilitated PPA: Verifies purity by demonstrating consistent precursor ions, product ions, and/or adducts across the peak.

- Two-dimensional liquid chromatography (2D-LC): Provides orthogonal separation mechanisms.

- Spiking studies: Adding impurity markers to verify separation.

FAQs: Understanding Green Solvent Metrics

What is the GSK Solvent Sustainability Guide, and what does it measure?

The GSK Solvent Sustainability Guide is a comprehensive tool developed by GlaxoSmithKline to help scientists objectively assess and compare the sustainability of solvents. It provides a single composite score and color assignment by combining evaluations across multiple health, environment, safety, and waste categories. The guide has been expanded to include many solvents claimed to be "green" and uses a transparent, published methodology to facilitate rank ordering based on multiple facets of sustainability [14].

How is the Analytical Method Greenness Score (AMGS) different?

The Analytical Method Greenness Score (AMGS) is a metric designed to summarize the environmental impact of an entire analytical method, such as a chromatography run, with a single number. A lower AMGS indicates a greener method. It factors in variables including instrumental power consumption, solvent hazard, solvent cumulative energy demand (based on production and disposal), and solvent waste generation. It was invented in 2019 by the American Chemical Society’s Green Chemistry Institute (ACS-GCI) to provide environmental impact awareness and encourage the development of greener analytical methods [15] [16].

Can these metrics be used for Gas Chromatography (GC) methods?

The GSK guide can be applied to the solvents used in any process, including GC. The official AMGS calculator currently supports Liquid Chromatography (LC) and Supercritical Fluid Chromatography (SFC) methods. The ACS GCI Pharmaceutical Roundtable is actively working on a version for Gas Chromatography, which is expected by early 2026 [16].

We must comply with USP <467> for residual solvents. How does green solvent selection fit in?

Regulations like USP <467> and ICH Q3C are designed to limit patient exposure to harmful residual solvents and are mandatory for compliance [17] [18]. Green solvent metrics complement these regulations by helping you select safer, more sustainable solvents during the development and manufacturing stages, which can simplify the final compliance testing and align with broader corporate sustainability goals [19].

What are some common pitfalls when switching to a green solvent?

A common short-sighted strategy is to simply replace a hazardous solvent with a structurally similar one, which may soon face its own regulatory restrictions. For example, benzene was replaced by toluene, which is now also regulated. A more robust approach is to use a structured guide, like the GSK guide, to evaluate the full environmental, health, and safety (EHS) profile of alternatives. Another pitfall is neglecting process efficiency; a green solvent used in an inefficient method with high energy consumption may not yield a favorable overall AMGS [19] [15].

Troubleshooting Guides

Issue 1: Poor Peak Resolution After Switching to a Green Solvent

Problem: After replacing a traditional solvent with a "greener" alternative in a GC method, you observe poor peak resolution, peak tailing, or co-elution.

Solution:

| Step | Action | Rationale |

|---|---|---|

| 1 | Verify Column Compatibility: Check if the stationary phase of your GC column is compatible with the new green solvent. | Some green solvents may have different polarity or chemical properties that require a different column chemistry for optimal separation [18]. |

| 2 | Optimize Temperature Program: Adjust the GC oven temperature ramp rate and final temperature. A slower ramp rate can improve separation of closely eluting peaks [20]. | The method's greenness is tied to its cycle time; a slightly slower ramp that fixes resolution may be greener than a fast run that requires repetition [15]. |

| 3 | Consider a Carbonic Acid Additive: If using aqueous mobile phases, consider generating carbonated water-based eluents. | Research shows that carbonic acid (H₂CO₃*) can reduce retention and sharpen peaks for native compounds, improving chromatographic figures of merit while maintaining greenness [15]. |

Issue 2: High AMGS in HPLC/GC Method

Problem: Your analytical method has a high Analytical Method Greenness Score, indicating a large environmental footprint.

Solution:

| Step | Action | Rationale |

|---|---|---|

| 1 | Scrutinize Solvent Choice: Use the GSK Solvent Guide to select a solvent with a better EHS profile. Replace Class 1/2 solvents with Class 3 or greener alternatives where possible [14] [19]. | The solvent hazard is a major component of the AMGS. Using a greener solvent directly lowers the score [16]. |

| 2 | Reduce Solvent Consumption: Switch to narrower diameter columns (e.g., with superficially porous particles) and reduce flow rates where feasible [15]. | This directly reduces the volume of solvent waste generated, which is a key term in the AMGS formula [15] [16]. |

| 3 | Shorten Run Time & Incorporate Cycle Time: Optimize the method for speed without compromising critical resolution. Factor in the instrumental cycle time (t_c) between injections in your calculations. |

Instrumental energy usage is another key component of the AMGS. Mathematical optimization shows that incorporating cycle time reveals an ideal flow rate for the greenest operation, which is not necessarily the fastest possible [15]. |

Experimental Protocols

Protocol 1: Implementing a Green GC-FID Method for Residual Solvent Analysis

This protocol is adapted from a study on analyzing dimethyl sulfoxide (DMSO) in paliperidone nanocrystals [20].

1. Goal: To develop a validated, green GC-FID method for the quantification of a residual solvent.

2. Materials:

- GC System: Gas Chromatograph with Flame Ionization Detector (FID).

- Column: Rtx-Wax or similar (30 m x 0.25 mm ID).

- Carrier Gas: Nitrogen or Helium.

- Diluent: Methanol (or another suitable, green solvent).

- Standards: Analytical standards of the target solvent (e.g., DMSO).

3. Method Configuration:

- Oven Program:

- Initial Temperature: 50°C

- Hold Time: 3 minutes

- Ramp Rate: 10°C per minute

- Final Temperature: 100°C

- Final Hold Time: 3 minutes

- Injector & Detector:

- Injection Mode: Split (define split ratio)

- Injector Temperature: As per method optimization

- Detector (FID) Temperature: 250°C

- Gas Flow:

- Carrier Gas Flow Rate: ~1 mL/min (optimize for retention time)

- Hydrogen/Air Flow for FID: As per manufacturer's recommendations.

4. Validation: Validate the method as per ICH Q2(R1) guidelines for:

- Specificity: No interference from other components.

- Linearity: Over a defined range (e.g., 2-10 µL/mL).

- Accuracy & Precision: (% Recovery and % RSD).

- LOD/LOQ: Determine Limit of Detection and Limit of Quantification.

5. Greenness Assessment: Calculate the AMGS for the final method using the ACS GCI PR calculator, focusing on its low solvent consumption, reduced waste generation, and energy-efficient operation [20] [16].

Protocol 2: Evaluating Solvents Using the GSK Guide Methodology

1. Goal: To select the greenest solvent for a chemical reaction or extraction process.

2. Procedure:

- Step 1: Identify Candidates: List all technically suitable solvents for the process.

- Step 2: Gather Data: For each solvent, collect data on:

- Health Hazards: Carcinogenicity, reproductive toxicity, mutagenicity, etc.

- Environmental Impact: Aquatic toxicity, biodegradability, bioaccumulation potential.

- Safety: Flash point, peroxide formation tendency.

- Lifecycle Impact: Cumulative Energy Demand (CED) for production and disposal [19].

- Step 3: Apply Scoring System: Use the published GSK methodology to assign scores to each criterion for every solvent [14].

- Step 4: Calculate Composite Score: Combine the individual scores, using the GSK's defined weighting, to generate a single composite sustainability score for each solvent.

- Step 5: Rank and Select: Rank the solvents from lowest (best) to highest (worst) composite score. Use this ranking, alongside technical performance data, to make the final solvent selection.

Essential Signaling Pathways and Workflows

Solvent Greenness Assessment Workflow

AMGS Optimization Logic

The Scientist's Toolkit: Research Reagent Solutions

Key Materials for Green Residual Solvent Analysis

| Item | Function | Green Consideration |

|---|---|---|

| Water (Headspace Grade) | Most common diluent for residual solvent analysis [18]. | The greenest solvent (Class 3). Preferred choice when technically feasible [19]. |

| γ-Valerolactone (GVL) | Green precursor solvent in device fabrication [21]. | A bio-based, low-toxicity solvent with favorable EHS profile [21] [19]. |

| Carbonic Acid (H₂CO₃*) Eluent | Aqueous mobile phase additive for HPLC [15]. | Reduces retention, sharpens peaks, and is MS-compatible, enhancing method greenness [15]. |

| Dimethyl Sulfoxide (DMSO) | Common solvent for APIs and formulations [20]. | Requires strict control as a residual solvent. Its use should be justified and levels monitored per ICH Q3C [18] [20]. |

| Narrow-Bore GC/LC Columns | Chromatographic separation [15]. | Reduce solvent consumption and waste generation, directly lowering the AMGS [15]. |

| GSK Solvent Sustainability Guide | Database for comparing solvent EHS profiles [14]. | Enables objective selection of safer, more sustainable solvents for processes [14] [19]. |

| AMGS Calculator | Software tool for scoring analytical methods [16]. | Provides a metric to benchmark and improve the environmental footprint of chromatographic methods [15] [16]. |

This technical support center is designed for researchers, scientists, and drug development professionals navigating the convergence of regulatory compliance and the adoption of green solvents in pharmaceutical development. A core challenge in this field is maintaining, and even improving, peak resolution in residual solvent analysis when transitioning from traditional to sustainable solvents. The guides and FAQs below provide targeted troubleshooting for specific experimental issues, framed within the context of a broader thesis on enhancing chromatographic performance. Our goal is to support the development of safer, more sustainable pharmaceuticals without compromising analytical rigor.

Core Concepts: Regulatory Frameworks & Green Solvents

Key Regulatory Guidelines on Residual Solvents

Regulatory agencies worldwide mandate the control of residual solvents in Active Pharmaceutical Ingredients (APIs), excipients, and drug products. These solvents, also called Organic Volatile Impurities (OVIs), provide no therapeutic benefit and can pose significant health risks, making their monitoring essential for patient safety [22].

| Regulatory Guideline | Scope & Key Focus | Legal Effective Date / Status |

|---|---|---|

| ICH Q3C (R9) [23] | Provides Permitted Daily Exposure (PDE) limits for residual solvents based on toxicity; the globally recognized standard. | Current effective version (R6); R9 is the latest scientific guideline. |

| USP General Chapter <467> [22] [24] | Provides enforceable limits and analytical procedures for residual solvents; harmonized with ICH Q3C but applies to all drug products, new and existing. | 20 November 2021 (for ICH Q3C(R8)-aligned version) [22]. |

| European Pharmacopoeia (Ph. Eur.) [22] | Provides general text 5.4 and general chapter 2.4.24 with analytical methods for residual solvent analysis. | Continuously updated. |

Residual solvents are classified based on their toxicity and environmental impact [24]:

- Class 1 Solvents: Known human carcinogens, strongly suspected human carcinogens, and environmental hazards. These must be avoided in the manufacture of drug substances, excipients, and drug products [25]. Examples include benzene (PDE 2 ppm) and carbon tetrachloride (PDE 4 ppm) [24].

- Class 2 Solvents: Non-genotoxic animal carcinogens, or solvents causing other irreversible toxicities such as neurotoxicity or teratogenicity. Their use should be limited [9]. Examples include methanol (PDE 3000 ppm), dichloromethane (PDE 600 ppm), and toluene (PDE 890 ppm) [24].

- Class 3 Solvents: Solvents with low toxic potential. These have PDEs of 50 mg or more per day and are considered less hazardous, though they must still be monitored [24]. Examples include acetone and ethanol (both with a limit of 5000 ppm) [25].

Understanding the Market Shift to Green Solvents

The pharmaceutical industry is increasingly adopting green solvents, driven by:

- Regulatory Pressure: Stricter environmental and workplace safety regulations aimed at reducing volatile organic compound (VOC) emissions and toxic waste [26] [27].

- Consumer Demand: Growing consumer awareness and preference for sustainably manufactured, eco-friendly products [26].

- Economic & Operational Benefits: Green solvents can lead to reduced waste disposal costs, lower energy consumption for solvent removal, and improved workplace safety due to non-flammability and reduced exposure risks [26] [27].

Common Green Solvents in Pharmaceutical Applications

Green solvents are characterized by low toxicity, biodegradability, and derivation from renewable resources [26] [27].

| Solvent Class | Examples | Key Properties & Common Applications |

|---|---|---|

| Water | N/A | Non-toxic, non-flammable, universal; used in extractions and reactions [26] [27]. |

| Supercritical Fluids | Supercritical CO₂ (scCO₂) | Non-toxic, recyclable; used in decaffeination, extraction of essential oils, and pharmaceutical synthesis [26] [27]. |

| Bio-Based Solvents | Ethyl Lactate, d-Limonene | Derived from renewable biomass (e.g., plants, citrus fruits); biodegradable; used in cleaning and degreasing [26]. |

| Ionic Liquids | Various organic salts | Negligible volatility, tunable properties; used in catalysis, separations, and electrochemical processes [26] [27]. |

| Deep Eutectic Solvents (DES) | Mixtures of, e.g., choline chloride and urea | Biodegradable, low-cost; used in synthesis, metal extraction, and bio-refining [26]. |

Troubleshooting Guides for Peak Resolution in Green Solvent Analysis

Guide 1: Poor Peak Shape and Broadening with Green Solvent Matrices

Issue: When using green solvents like ionic liquids or deep eutectic solvents as sample diluents, peaks in the gas chromatogram appear broad, tailing, or fronting, leading to poor resolution.

Background: The high viscosity and non-volatile nature of many green solvents can lead to inefficient vaporization and transfer in the GC inlet, or cause column interactions that degrade peak shape.

Solution:

- Optimize Headspace Parameters: For headspace-GC, increase the oven temperature and equilibration time to ensure complete transfer of volatile analytes from the complex matrix. A study analyzing solvents in Paclitaxel used an oven temperature of 80°C and an equilibration time of 30 minutes [9]. Similarly, a method for Tigecycline used an oven temperature of 80°C and a pressurization time of 5.0 minutes [28].

- Adjust Inlet Conditions: If using direct injection, ensure the injector temperature is sufficiently high (e.g., 210°C [28]) and consider using a higher split ratio (e.g., 30:1 [28]) to minimize the amount of non-volatile matrix entering the column.

- Select a Robust Diluent: A study successfully used a mixture of N-methyl-2-pyrrolidinone (contains 1% piperazine) and water (80:20 v/v) to analyze residual solvents in Paclitaxel, achieving good sensitivity and peak shape [9]. The addition of water can help modulate the solution's properties.

Guide 2: Co-elution of Solvents in Complex Mixtures

Issue: Multiple residual solvent peaks are not fully separated (co-elution), making accurate identification and quantification impossible.

Background: This is often due to an inadequately selective chromatographic column or a non-optimal temperature program for the specific solvent mixture.

Solution:

- Column Selection: Use a mid-to-high polarity column designed for volatile organic analysis. The DB-624 column (6% cyanopropylphenyl / 94% dimethyl polysiloxane) is widely used and recommended in pharmacopeial methods. It has been successfully employed for separating complex mixtures, including methanol, ethanol, acetone, and dichloromethane [9] [28].

- Optimize the Oven Temperature Program: A multi-ramp program is often necessary. Start with a low initial temperature to separate highly volatile solvents, then ramp to separate mid- and high-boiling solvents.

- Example Program from Literature: 40°C hold for 6 min, then ramp at 100°C/min to 220°C hold for 5 min [28].

- Confirm System Suitability: Before sample analysis, ensure the method meets system suitability criteria. The resolution (R) between the two most critical peaks should be not less than 1.5, and the theoretical plate count (N) should be not less than 5000 [28].

Guide 3: High Background Noise or Ghost Peaks

Issue: The chromatographic baseline is noisy, or unexpected peaks ("ghost peaks") appear, interfering with the analysis of target solvents.

Background: This can be caused by contaminants in the carrier gas, septa, column bleed, or impurities in the green solvents themselves.

Solution:

- Use High-Purity Solvents and Gases: Ensure that all solvents used for preparing standards and samples are of high purity (e.g., "headspace grade") to minimize introduction of volatile impurities. Use high-purity (e.g., 99.998% or better) carrier gas such as nitrogen or helium [24] [28].

- Run a Blank: Always inject a blank (the diluent alone) to identify the source of contamination. The blank chromatogram should show no interference at the retention times of the target analytes [9] [28].

- Maintain the Instrument: Regularly maintain the GC system by cutting the column inlet, replacing the inlet liner and septa, and performing conditioning steps as needed.

Frequently Asked Questions (FAQs)

Q1: Are ICH Q3C and USP <467> fully harmonized? While ICH Q3C and USP <467> are harmonized in their PDE limits and general approach, a key difference exists in their scope. ICH Q3C typically applies to new drug products, whereas USP <467> applies the same requirements to all drug products, both new and existing [24].

Q2: What is the recommended analytical technique for residual solvent analysis? Headspace Gas Chromatography (HS-GC) is considered the gold standard. It is coupled with either a Flame Ionization Detector (FID) for routine quantification or Mass Spectrometry (GC-MS) for confirming the identity of unknown solvents [22] [24] [25]. This technique avoids introducing non-volatile sample matrices into the GC system.

Q3: My sample is insoluble in water, the preferred green diluent. What are my alternatives? While water is the ideal green solvent, many drug substances are insoluble. In such cases, other solvents like dimethyl sulfoxide (DMSO), N,N-dimethylformamide (DMF), or N-methyl-2-pyrrolidinone (NMP) can be used [24] [9]. It is critical to ensure these diluents are of high purity (headspace grade) to avoid introducing interfering peaks.

Q4: What are the main challenges in adopting green solvents at an industrial scale? Despite their benefits, challenges remain, including:

- Scalability and Cost: The production of some green solvents (e.g., certain ionic liquids) remains expensive at large scales [26] [27].

- Performance Data: A lack of comprehensive data on long-term stability, toxicity, and performance under diverse industrial conditions [26].

- Process Changes: Transitioning from established processes may require significant investment in new equipment and process re-validation [27].

Q5: How do I validate an analytical method for residual solvents? Method validation should be performed per ICH Q2 guidelines. Key parameters to establish include: Specificity (no interference), Precision (%RSD not more than 15.0%), Linearity (from LOQ to 150% of the target level), Accuracy (acceptable recovery), and Robustness [9] [28]. The Limit of Detection (LOD) and Limit of Quantitation (LOQ) must also be determined for each solvent [9].

Experimental Workflow for Method Development

The following diagram illustrates a logical workflow for developing and validating a GC-HS method for residual solvent analysis, incorporating considerations for green chemistry.

The Scientist's Toolkit: Essential Research Reagents & Materials

The following table details key materials and reagents essential for conducting robust residual solvent analysis, with a focus on achieving high peak resolution.

| Item / Reagent | Function / Purpose | Key Considerations for Performance |

|---|---|---|

| DB-624 GC Column | A mid-polarity stationary phase designed for the separation of volatile organic compounds. | Provides excellent resolution for a wide range of Class 1, 2, and 3 solvents [9] [28]. |

| Headspace Grade Solvents | High-purity solvents (Water, DMSO, DMF, NMP) used to dissolve the sample. | Critical for minimizing background noise and ghost peaks; essential for achieving low LOD/LOQ [24]. |

| Certified Reference Standards | High-purity solvents for preparing calibration standards. | Required for accurate identification and quantification; ensures data integrity for regulatory compliance [9] [28]. |

| High-Purity Carrier Gas | Nitrogen or helium used to carry the sample through the GC column. | Purity (≥99.998%) is essential for stable detector baseline and sensitivity, especially with FID [24]. |

| Inert Headspace Vials/Septa | Containers and seals for headspace sampling. | Must be inert and sealed properly to prevent loss of volatiles and ensure reproducible results [9]. |

The Environmental and Business Case for Greening Chromatographic Methods

Chromatographic techniques, while foundational to modern analytical laboratories, pose significant environmental challenges. A single liquid chromatograph can generate 1 to 1.5 liters of solvent waste per day, translating to approximately 500 liters of waste annually per instrument [29] [30]. With an estimated 13,000 HPLC devices operating worldwide, this results in the consumption of around 34 million liters of solvent per year [30]. Beyond waste generation, traditional chromatographic methods often employ hazardous solvents like acetonitrile and hexane, which pose health risks and environmental concerns [29] [30].

The "green chromatography" paradigm addresses these issues by minimizing resource consumption and replacing toxic reagents with safer alternatives throughout the analytical workflow [30]. This approach aligns with the 12 principles of green chemistry and offers compelling business advantages, including reduced operating costs, improved workplace safety, and enhanced regulatory compliance [29]. This technical support center provides practical guidance for researchers, scientists, and drug development professionals seeking to implement greener chromatographic methods while maintaining or improving analytical performance.

Troubleshooting Guide: Transitioning to Greener Methods

Adopting green chromatographic methods can present specific challenges. The table below addresses common issues and provides evidence-based solutions.

Table 1: Troubleshooting Guide for Green Chromatography Methods

| Problem | Potential Causes | Recommended Solutions | Supporting Research |

|---|---|---|---|

| Poor Peak Resolution with Green Solvents | High viscosity of solvents like ethanol causing backpressure and efficiency loss [30]. | - Use UHPLC systems designed for higher pressure [30].- Increase column temperature to reduce solvent viscosity [30].- Employ twin-column recycling chromatography to increase effective column length and resolution [31]. | Separation of cannabinoids achieved with pure ethanol via recycling chromatography, overcoming co-elution [31]. |

| Peak Tailing with Alternative Mobile Phases | Secondary interactions with residual silanol groups on the stationary phase, especially for basic compounds [32]. | - Use Deep Eutectic Solvents (DES) as mobile phase additives to block silanol groups [32].- Consider alternative stationary phases designed for green solvents. | DES additives like ChCl:Gly significantly suppressed tailing of basic alkaloids, improving peak symmetry and column efficiency [32]. |

| Long Analysis Times & High Solvent Consumption | Method not optimized for speed and minimal solvent use. | - Apply in-silico modeling to map separation landscape and rapidly identify optimal conditions [33].- Shift to smaller column dimensions (e.g., UHPLC, micro-HPLC) [30].- Replace acetonitrile with methanol or ethanol-water mixtures [33] [34]. | In-silico modeling reduced the Analytical Method Greenness Score (AMGS) from 7.79 to 5.09 by replacing acetonitrile with methanol while preserving resolution [33]. |

| Method Performance Failure After Solvent Substitution | Direct 1:1 solvent replacement without re-optimization of other method parameters. | - Systematically re-optimize the method using a Quality by Design (QbD) approach with tools like Fractional Factorial and Box-Behnken designs [34].- Use predictive modeling to understand the new separation landscape [33]. | A QbD paradigm successfully optimized a green stability-indicating method using isopropanol and buffer, achieving analysis in four minutes [34]. |

| Detecting Residual Solvents in Final Product | Lack of sensitive, green methods for monitoring solvent residues from manufacturing. | - Implement robust quantification methods as per ICH guidelines [8].- Explore solvent-free alternatives or Generally Recognized as Safe (GRAS) solvents like ethanol for production [31] [8]. | Ethanol is classified as a fully "recommended" solvent with no negative effects on environment and humans, and is GRAS [31]. |

Experimental Protocols for Greener Chromatography

Protocol: In-silico Modeling for Method Greening

This protocol uses computer-assisted modeling to rapidly develop greener methods without extensive laboratory experimentation [33].

Materials:

- Software: LC Simulator (e.g., ACD Labs) or equivalent.

- Instrument: Standard UHPLC system (e.g., Agilent 1290).

- Columns: As required for separation (e.g., C18).

- Solvents: Candidates for substitution (e.g., methanol, ethanol).

Method:

- Initial Data Collection: Run a limited set of initial experiments (e.g., 8 temperatures and 10 gradient times) to profile the sample's behavior.

- Model Building: Input the experimental data into the modeling software to predict the separation landscape (resolution, retention times) across all possible method conditions.

- Greenness Mapping: Calculate the Analytical Method Greenness Score (AMGS) for each predicted method condition. The AMGS formula for chromatography is [33]:

AMGS = [R * (ta + tc) * (F * S * C + E)] / NWhere: R=replicates, ta=analysis time, tc=cycle time, F=flow rate, S=solvent safety/health/environment index, C=solvent cumulative energy demand, E=instrument energy demand, N=number of analytes. - Optimal Condition Selection: Identify method conditions that simultaneously meet the required resolution targets and offer the lowest possible AMGS.

- Verification: Experimentally verify the predicted optimal method.

Application Example: Replacing a fluorinated additive (TFA) with a chlorinated one (TCA) was achieved using this workflow. The AMGS was reduced from 9.46 to 4.49, while resolution for a critical pair improved from fully overlapped to 1.40 [33].

Protocol: Twin-Column Recycling Chromatography with Ethanol

This protocol is designed for challenging separations where green solvents like ethanol provide insufficient resolution in a single pass [31].

Materials:

- Instrument: HPLC system capable of twin-column recycling (requires an 8-port-2-position valve).

- Columns: Two identical reversed-phase columns (e.g., C18).

- Mobile Phase: Pure ethanol (HPLC grade) [31].

- Samples: Cannabis extract rich in CBD, for THC depletion.

Method:

- System Setup: Connect two identical columns via an 8-port-2-position valve with a UV detector placed between them.

- Sample Injection: Load the sample onto the first column.

- Recycling Process: The valve is switched at predetermined times so the eluting peaks are directed from the outlet of the first column into the inlet of the second, and vice-versa. Each switch increases the total number of columns the sample has experienced (

n_tot = n_s + 2, wheren_sis the number of switches). - Separation Monitoring: Use the internal UV detector to monitor the separation progress in real-time. The resolution increases with each cycle.

- Fraction Collection: Once the target compounds are fully resolved (e.g., CBD separated from THC), the peaks are directed to the outlet for collection.

Application Example: This method achieved complete removal of THC from a CBD-rich cannabis extract using pure ethanol as the mobile phase, a solvent classified as safe for food and pharmaceutical products [31].

Visual Workflow: Greening a Chromatographic Method

The diagram below outlines a logical pathway for developing and troubleshooting a greener chromatographic method.

Greening Method Development Workflow

Research Reagent Solutions for Green Chromatography

The table below catalogs key materials and solvents that facilitate the development of greener chromatographic methods.

Table 2: Key Reagents and Materials for Green Chromatography

| Reagent/Material | Function | Green Advantage & Example Use |

|---|---|---|

| Methanol / Ethanol | Replacement for acetonitrile as the organic modifier in reversed-phase LC [33] [30]. | Lower environmental and health impact; In-silico modeling enabled a switch from ACN to MeOH, reducing the AMGS from 7.79 to 5.09 [33]. |

| Trichloroacetic Acid (TCA) | Replacement for per- and polyfluoroalkyl substances (PFAS) additives like Trifluoroacetic Acid (TFA) [33]. | Avoids the use of persistent "forever chemicals"; Successfully used as a mobile phase additive where a switch from TFA reduced AMGS from 9.46 to 4.49 [33]. |

| Deep Eutectic Solvents (DES) | Mobile phase additive or stationary phase modifier [32]. | Biodegradable, low toxicity, and recyclable; Used as an additive to reduce organic solvent content and improve peak shape of basic compounds [32]. |

| Supercritical CO₂ | Primary mobile phase in Supercritical Fluid Chromatography (SFC) [30]. | Non-toxic, no disposal needed; Used with max. 30% polar solvents like methanol or ethanol for a wide range of separations with minimal waste [30]. |

| Water (at elevated T) | Mobile phase component or sole solvent in pure aqueous chromatography. | Non-toxic and readily available; Higher temperatures reduce viscosity and can elute more hydrophobic compounds without organic modifiers. |

| Twin-Column Recycling System | Hardware setup to increase effective column length without ultra-high pressure [31]. | Enables use of low-elution-strength green solvents (e.g., pure EtOH) by providing more theoretical plates to achieve difficult separations [31]. |

Frequently Asked Questions (FAQs)

Q1: What is the simplest way to start making my HPLC methods greener? The most straightforward approach is to substitute solvents. Replace acetonitrile with methanol or ethanol where possible [30]. Additionally, you can reduce the column dimensions (e.g., switch from a 4.6 mm ID column to a 2.1 mm ID column), which directly decreases mobile phase consumption and waste generation by approximately 80% for the same linear velocity [30].

Q2: Is ethanol really a viable replacement for acetonitrile in reversed-phase HPLC? Yes, but it may require method re-optimization. Ethanol has a higher viscosity than acetonitrile, which can lead to higher backpressure. This can be mitigated by using a UHPLC system that operates at higher pressures or by increasing the column temperature to lower the solvent's viscosity [30]. The elution strength of ethanol also differs from acetonitrile, so gradient profiles may need adjustment [33].

Q3: How can I objectively measure and compare the "greenness" of my chromatographic methods? You can use quantitative metrics. The Analytical Method Greenness Score (AMGS), developed by the ACS Green Chemistry Institute Pharmaceutical Roundtable, is a dedicated metric for chromatography. It considers analysis time, flow rate, solvent type, and energy consumption, with lower scores indicating greener methods [33]. Free online calculators for AMGS are available.

Q4: My method uses trifluoroacetic acid (TFA). Why is this a problem, and what are the alternatives? TFA is a per- and polyfluoroalkyl substance (PFAS), often called a "forever chemical" due to its extreme environmental persistence and potential health risks. Regulatory bodies are moving to restrict its use. Effective alternatives include trichloroacetic acid (TCA), formic acid, or acetic acid, though method performance should be carefully verified after switching [33].

Q5: What is the role of in-silico modeling in green chromatography? In-silico modeling is a powerful tool for green method development. It uses data from a limited set of experiments to predict optimal separation conditions across a wide range of parameters (temperature, gradient, pH). This dramatically reduces the number of laboratory experiments required, saving time, solvents, and energy, making the development process itself greener [33].

Strategies for Integrating Green Solvents and Optimizing Resolution

In the pharmaceutical industry and drug development, residual solvent analysis is a critical quality control step to ensure that traces of solvents used in manufacturing are within safe limits. The drive towards green chemistry has intensified the focus on replacing hazardous solvents with safer, more sustainable alternatives. This transition not only improves environmental and workplace safety but can also enhance analytical performance. A systematic approach to solvent substitution, centered on Hansen Solubility Parameters (HSP) and dedicated online tools, enables researchers to identify alternatives that maintain solvation power while minimizing health, safety, and environmental (EHS) concerns. This guide provides troubleshooting and methodological support for scientists integrating green solvents into their analytical workflows.

Understanding the Core Concepts

What Are Green Solvents?

Green solvents are environmentally friendly solvents derived from the processing of agricultural crops or other sustainable methods, developed as alternatives to petrochemical solvents [35]. They are characterized by a combination of:

- Low health hazard

- High safety (e.g., non-flammable, chemically stable)

- Low environmental impact throughout their life cycle [36]

- Ease of recycling and biodegradability [35]

It is important to note that "green" is a relative term. A solvent's suitability must be evaluated against the specific requirements of its application, and even petrochemical-derived solvents can possess "green characteristics" if their EHS profile is superior to that of traditional options [35].

The Role of Hansen Solubility Parameters (HSP)

The "like-dissolves-like" rule is quantified for practical application using Hansen Solubility Parameters (HSP) [36]. This method separates the total cohesion energy of a solvent into three parameters, each measuring a different type of intermolecular force:

- δD (Dispersion forces): Molecular dispersion interactions.

- δP (Polar interactions): Molecular dipolar interactions.

- δH (Hydrogen bonding): Molecular hydrogen bonding interactions [36].

The similarity in solubility capacity between two solvents is determined by their proximity in this 3D Hansen space. The distance, Ra, is calculated as:

Ra² = 4(δD1 - δD2)² + (δP1 - δP2)² + (δH1 - δH2)² [36]

A smaller Ra value indicates a higher probability that two solvents will dissolve the same solute, making HSP a powerful tool for identifying functional green alternatives.

| Tool / Resource | Function & Purpose | Key Features & Examples |

|---|---|---|

| Online Green Solvent Tool [36] | Identifies green alternative solvents based on HSP and sustainability scores. | Ranks solvents by Ra distance; provides health, safety, and environmental data; color-coded sustainability scoring (Green/Yellow/Red). |

| Hansen Solubility Parameters [36] | Predicts solvation power and identifies solvents with similar dissolution capacity. | Uses δD, δP, δH parameters to calculate relative distance (Ra) between solvents and solutes. |

| GSK Solvent Sustainability Guide [19] [36] | Provides a quantitative composite score (G) for solvent sustainability. | Evaluates health, safety, environmental, and waste disposal categories; scores from 1 (non-sustainable) to 10 (sustainable). |

| ACS Green Chemistry Institute Resources [37] | Offers science-based tools and guidance for solvent selection. | Incorporates research from pharmaceutical roundtables; provides solvent selection guides. |

| Bio-based Solvents [37] [35] | Serves as sustainable, renewable alternatives to petrochemical solvents. | Examples: 2-Methyltetrahydrofuran (2-MeTHF), Cyrene, ethyl lactate, d-limonene. |

A Step-by-Step Experimental Protocol for Solvent Substitution

This protocol is adapted from a green analytical chemistry approach for lipid extraction, demonstrating a methodology applicable to residual solvent analysis [38].

Objective: To replace a hazardous solvent (e.g., hexane) with a green alternative for an analytical process while maintaining or improving performance.

Materials:

- Target analyte (e.g., active pharmaceutical ingredient).

- Conventional solvent (e.g., hexane, DCM, DMF).

- Candidate green solvents (e.g., 2-MeTHF, cyclopentyl methyl ether (CPME), ethyl acetate, dimethyl carbonate) [37] [38].

- Standard laboratory equipment (vials, balances, GC-MS/HPLC system).

Methodology:

- In Silico Screening with HSP:

Experimental Solubility Testing:

- Prepare saturated solutions of your analyte in each candidate solvent and the conventional solvent.

- Shake or stir the mixtures for a defined period at a constant temperature.

- Analyze the concentration of the dissolved analyte using a suitable technique (e.g., UV-Vis, HPLC).

Chromatographic Performance Evaluation:

- Prepare standard solutions of the analyte and potential residual solvents in the selected green alternatives.

- Perform chromatographic analysis (e.g., GC-FID as in [39]) and compare key parameters with the conventional method:

- Peak resolution and shape.

- Retention time stability.

- Signal-to-noise ratio and sensitivity.

Data Analysis and Selection:

- The solvent that provides comparable or better solubility and chromatographic performance to the conventional solvent, coupled with a greener EHS profile, should be selected for further validation.

The workflow for this protocol is summarized in the diagram below:

Troubleshooting Common Issues in Green Solvent Substitution

FAQ 1: The green solvent I selected using HSP has poor solubility for my analyte. Why?

- Cause: HSP predicts thermodynamic solubility based on cohesion energy, but the dissolution kinetics might be slower. The solute-solvent interactions may not be as favorable as predicted, or the solvent's viscosity could be impeding dissolution.

- Solution:

- Verify the HSP of your solute experimentally if possible, as database values can be approximate.

- Consider using a solvent blend. A mixture of two green solvents can yield HSPs that match your solute better than a single solvent [36].

- Evaluate other physical properties (e.g., viscosity, boiling point) that might affect the extraction or dissolution process.

FAQ 2: My green alternative is causing poor peak resolution or shape in GC analysis.

- Cause: The alternative solvent may have different polarity, viscosity, or solvent strength, affecting the interaction of analytes with the stationary phase. It could also introduce new impurities.

- Solution:

- Re-optimize chromatographic parameters: Adjust the oven temperature ramp, carrier gas flow rate, and injection port temperature specific to the new solvent [39].

- Check for solvent-solute interactions: Ensure the green solvent does not react with or degrade the analytes.

- Purify the solvent: Use high-purity grades to eliminate interfering contaminants.

FAQ 3: The "greenest" solvents (e.g., water, ionic liquids) are not suitable for my application. What should I do?

- Cause: A universal green solvent does not exist [40] [41]. The ideal solvent is application-specific.

- Solution:

- Follow the waste minimization hierarchy: First, aim to avoid or reduce solvent use, then recover and recycle, and finally, dispose of safely [40] [41].

- Use a solvent selection guide (e.g., from GSK or ACS) to find the "best in class" option for your needs. A solvent with minor concerns that is used with proper precautions is often an acceptable step forward from a highly hazardous one [37].

Quantitative Data for Common Solvents and Substitutions

The following tables provide a concise overview of solvent sustainability and common substitutions to aid in the selection process.

Table 1: Sustainability and HSP Data for Common Solvents [37] [36]

| Solvent | GSK Sustainability Score (G) [36] | Health/Safety/Environmental Notes | δD | δP | δH |

|---|---|---|---|---|---|

| Ethyl Acetate | Information Missing | Ester, generally favorable profile | 7.2 | 2.3 | 4.5 |

| 2-MeTHF | Information Missing | Bio-based, preferable to THF | 8.2 | 2.2 | 3.2 |

| Cyclopentyl Methyl Ether (CPME) | Information Missing | Better than traditional ethers | 7.1 | 1.6 | 2.1 |

| Heptane | Information Missing | Less neurotoxic than hexane | 7.5 | 0.0 | 0.0 |

| Dimethyl Carbonate | Information Missing | Polar aprotic alternative | 8.5 | 3.1 | 2.1 |

| Dimethyl Sulfoxide (DMSO) | Information Missing | Some concerns, use with caution [37] | 9.0 | 4.4 | 2.5 |

| N,N-Dimethylformamide (DMF) | 3.7 (Red) [37] | Reprotoxic, significant concerns [37] [19] | 8.5 | 3.9 | 3.5 |

| Dichloromethane (DCM) | Information Missing | Carcinogenic, ozone-depleting [37] [19] | 8.7 | 3.1 | 3.0 |

| Hexane | Information Missing | Neurotoxic, significant concerns [37] | 7.3 | 0.0 | 0.0 |

| Toluene | Information Missing | Suspected reprotoxin, some concerns [37] [19] | 8.0 | 0.7 | 1.0 |

Table 2: Common Hazardous Solvents and Their Recommended Green Alternatives [37]

| Hazardous Solvent | Primary Concerns | Recommended Green Alternatives |

|---|---|---|

| Dichloromethane (DCM) | Carcinogenicity, environmental impact | 2-MeTHF, Cyclopentyl Methyl Ether (CPME) |

| N,N-Dimethylformamide (DMF) | Reproductive toxicity | Cyrene, Dimethyl Carbonate |

| Hexane | Neurotoxicity | Heptane, Limonene (for extractions) |

| Toluene | Reproductive toxicity, organ damage | Anisole, p-Cymene (bio-based) |

The transition to green solvents in residual solvent analysis and pharmaceutical development is a tangible and critical goal. By leveraging a systematic framework that combines Hansen Solubility Parameters for predicting functionality with comprehensive sustainability guides for assessing EHS impact, researchers can make informed, scientifically sound decisions. The tools and protocols outlined in this guide provide a clear path for troubleshooting substitution challenges, ultimately leading to safer, more sustainable, and high-performing analytical methods.

Replacing acetonitrile (ACN) with methanol (MeOH) in analytical methods like Residual Solvent Analysis (RSA) is a significant step toward adopting Green Analytical Chemistry principles. This switch is driven by methanol's lower environmental impact, reduced toxicity, and lower cost, while still maintaining strong chromatographic performance [42] [43]. Methanol is classified as a Class 2 solvent with a permitted daily exposure (PDE) of 3000 ppm, whereas acetonitrile is also a Class 2 solvent but with a lower PDE of 410 ppm, reflecting its higher toxicity [18] [25].

From a mechanistic standpoint, the success of this substitution hinges on understanding the solvent selectivity triangle [44]. Methanol, acetonitrile, and tetrahydrofuran (THF) occupy different regions of this triangle due to their distinct acidic, basic, and dipolar properties. Methanol exhibits stronger acidic (proton-donating) properties, which can alter selectivity and peak spacing for compounds that interact through hydrogen bonding, compared to the predominantly dipolar character of acetonitrile [44].

Experimental Protocol: Method Conversion from Acetonitrile to Methanol

Materials and Equipment

- Chromatograph: GC-MS system equipped with a headspace autosampler (e.g., TriPlus 500) [18].

- Column: GC column suitable for residual solvent analysis (e.g., a cyanopropylphenyl polysiloxane phase) [18].

- Standards: Certified reference materials for target residual solvents (e.g., methanol, acetone, dichloromethane) and internal standards if required.

- Solvents: HPLC or MS-grade Methanol and Acetonitrile [42] [45].

- Samples: Drug substances or finished products for testing.

Step-by-Step Procedure

Initial Method Conditions: Begin with your original acetonitrile-based GC-MS method. A typical starting point for a headspace GC-MS method for RSA might be [18]:

- Column: 30m x 0.32mm, 1.8µm cyanopropylphenyl column

- Oven Program: 40°C for 20 minutes, then ramp to 240°C at 10-20°C/min.

- Carrier Gas: Helium, constant flow.

- Headspace Conditions: Varies based on instrument, e.g., vial equilibration at 80-120°C.

Direct Solvent Substitution: Replace acetonitrile with methanol as the sample diluent. Ensure the sample is fully soluble in methanol. Use the same initial chromatographic conditions.

System Suitability Test: Run a system suitability mixture containing your target solvents. Assess critical parameters such as resolution, peak shape (tailing factor), and signal-to-noise ratio [17].

Method Optimization (if needed):

- Retention and Elution Strength: Methanol has different eluotropic strength compared to ACN in LC, but in GC, the primary effect is on the sample solution. The main chromatographic parameters (oven program, flow rate) might require fine-tuning to achieve optimal separation [44].

- Peak Shape: If peak tailing occurs, consider checking the injection port liner or the column condition, as the change in solvent properties can affect vaporization and interaction with the active sites in the system.

- Headspace Parameters: The change in solvent may affect partitioning in the headspace vial. You may need to optimize equilibration temperature and time to achieve the required sensitivity [18].

Validation: Once optimal conditions are found, validate the method according to ICH/ USP <467> guidelines to ensure it meets requirements for specificity, accuracy, precision, linearity, and robustness [17].

Troubleshooting Common Issues

Problem 1: Poor Peak Resolution or Co-elution

- Potential Cause: Methanol's different selectivity has altered the relative retention times of the solvents.

- Solution: Fine-tune the GC oven temperature ramp rate. A slower ramp rate will generally improve resolution. As a last resort, consider using a different GC stationary phase that provides better selectivity for the critical pair of solvents when methanol is used as a diluent [44].

Problem 2: Inadequate Sensitivity

- Potential Cause: The partitioning of volatile analytes between the sample solution (in methanol) and the headspace gas phase is different than with acetonitrile.

- Solution: Optimize headspace conditions. Increase the vial equilibration temperature to drive more analytes into the headspace. Adjust the sample solution concentration or vial volume if possible [18].

Problem 3: Formation of Methanol Adducts or Artifacts (in LC-MS)

- Potential Cause: Some analytes can form stable adducts with methanol molecules ([M+MeOH+H]+), which can be observed as extra peaks, particularly in LC-MS analysis. This has been documented with certain pesticides and other compounds [46].

- Solution: If transferring an LC-MS method, this is a critical consideration. To prevent adduct formation:

- Change the sample diluent to a solvent other than methanol (e.g., water or acetonitrile) if the method mobile phase is being changed to methanol.

- Adjust the ionization source parameters in the mass spectrometer to promote the formation of the primary ion (e.g., [M+H]+) and destabilize the methanol adduct.

- In some cases, using a methanol-containing mobile phase can actually cause these adducts to co-elute as a single peak, mitigating the issue [46].

Problem 4: Increased System Backpressure (in LC)

- Potential Cause: Methanol-water mixtures have a higher viscosity than acetonitrile-water mixtures, especially at certain ratios (e.g., ~40-60% organic), leading to higher system pressure [42].

- Solution: Reduce the flow rate slightly to bring the pressure back to an acceptable range. Ensure the system and column are rated for the expected pressure increase.

Frequently Asked Questions (FAQs)

Q1: Is methanol always a suitable direct replacement for acetonitrile? A: Not always. The suitability depends on the specific analytes and the separation mechanism. While methanol often provides comparable or even superior selectivity, it must be evaluated on a case-by-case basis. Factors like viscosity, UV cutoff, and potential for adduct formation must be considered [42] [44].

Q2: How does the methanol substitution impact regulatory compliance, specifically for USP <467>? A: The substitution itself does not impact regulatory compliance negatively, as both are permitted solvents. The analytical method, whether using MeOH or ACN as a diluent, must be fully validated and demonstrate that it can accurately quantify and control residual solvent levels per the limits set in USP <467> and ICH Q3C [17] [25]. Methanol, being a Class 2 solvent with a limit of 3000 ppm, must itself be controlled in the final product [18].

Q3: What are the primary green chemistry advantages of using methanol over acetonitrile? A: The advantages are multi-fold:

- Toxicity: Methanol has a higher PDE (3000 ppm vs. 410 ppm), indicating lower toxic risk [18] [25].

- Environmental Impact: Acetonitrile is derived from fossil fuels and metabolizes to hydrogen cyanide, whereas bio-based methanol is a more sustainable and renewable option [42] [43].

- Cost: Methanol is significantly less expensive than acetonitrile, both in purchase price and hazardous waste disposal [42].

Q4: Can I use a method that employs a methanol/water mobile phase for an LC-MS assay? A: Yes, water-methanol mixtures are widely used in LC-MS, often with additives like formic acid or ammonium acetate to enhance ionization. They are a popular and effective alternative to acetonitrile-based mobile phases [45].

Table 1: Comparison of Key Solvent Properties for Greenness Assessment

| Property | Acetonitrile (ACN) | Methanol (MeOH) | Greenness Advantage |

|---|---|---|---|

| ICH Classification | Class 2 | Class 2 | Comparable |

| PDE (Permitted Daily Exposure) | 410 ppm [18] | 3000 ppm [18] | MeOH (Higher PDE = Safer) |

| Solvent Selectivity | Strong dipole [44] | Acidic/Proton-donor [44] | Complementary |

| Viscosity (with water) | Lower [42] | Higher [42] | ACN (Lower backpressure) |

| UV Cutoff | ~190 nm [42] | ~205 nm [42] | ACN (Better for low UV) |

| Toxicity | Metabolizes to hydrogen cyanide [42] | Neurotoxic [42] | MeOH (Generally lower risk) |

| Cost & Supply | High, variable [42] [44] | Low, stable [42] | MeOH |

| Environmental Impact | High, hazardous waste [42] | Lower, bio-based options [43] | MeOH |

Table 2: Essential Research Reagent Solutions

| Reagent / Material | Function in Experiment | Specification / Critical Note |

|---|---|---|

| Methanol (MeOH) | Primary replacement solvent for acetonitrile as sample diluent and/or in mobile phase (LC). | HPLC-MS grade purity to prevent contamination, background noise, and ghost peaks [42] [45]. |

| Residual Solvent Standards | Used for calibration, qualification, and system suitability testing. | Certified Reference Materials (CRMs) from accredited suppliers (e.g., AccuStandard) to ensure data integrity and regulatory compliance [46]. |

| Headspace Vials & Septa | Contain the sample for volatile analysis in a closed system. | Must be chemically inert and capable of withstanding pressure and temperature without leaking or absorbing analytes. |

| GC Capillary Column | The stationary phase for separating volatile residual solvents. | Typically a mid-polarity phase (e.g., 6% cyanopropylphenyl / 94% polydimethylsiloxane) is used for USP <467> methods [18]. |

| Formic Acid / Ammonium Acetate | Common mobile phase additives in LC-MS to improve ionization efficiency and peak shape. | MS-grade purity (≥99%) [45]. Typically used at 0.1% (v/v) for acids or 2-10 mM for buffers. |

Experimental Workflow and Signaling Pathways

For researchers in drug development, achieving sufficient peak resolution (Rₛ) is a critical step in developing robust and reliable chromatographic methods, especially for sensitive applications like residual solvent analysis. The resolution value quantitatively describes the separation between two adjacent peaks in a chromatogram. This technical guide explores the core equation governing resolution, provides targeted troubleshooting advice, and discusses its specific application within the framework of green chemistry and regulatory compliance for residual solvent analysis.

Understanding the Resolution Equation

What is the Chromatographic Resolution Equation?

Chromatographic resolution is a measure of the separation between two peaks of different retention times. The fundamental equation, as defined by IUPAC, is expressed as:

Rₛ = 2 × (tᵣ₂ - tᵣ₁) / (w₆₁ + w₆₂)

Where:

- tᵣ₂ and tᵣ₁ are the retention times of the two peaks.

- w₆₁ and w₆₂ are the widths of the peaks at baseline [47].

An alternative, more widely used form of the equation is:

Rₛ = (tᵣ₂ - tᵣ₁) / [0.5 × (w₁ + w₂)]

Here, the difference in retention times is divided by the average of the two peak widths [6] [48]. This equation clearly shows that resolution can be improved either by increasing the distance between peak maxima or by decreasing (narrowing) the peak widths.

The Practical Meaning of Resolution Values

The calculated resolution value corresponds to a specific degree of separation between two Gaussian peaks of equal area [49] [6]. The following table summarizes the practical implications of different Rₛ values.

Table 1: Interpretation of Chromatographic Resolution Values

| Resolution (Rₛ) | Degree of Separation | Visual Valley Between Peaks | Peak Overlap (for equal peaks) | Typical Quantitative Use |

|---|---|---|---|---|

| Rₛ = 0.5 | Poor separation | Very shallow or none | ~16% overlap | Unsuitable |

| Rₛ = 1.0 | Partial separation | Distinct but significant valley | ~2.3% overlap [49] | May be sufficient for some qualitative analyses |

| Rₛ = 1.5 | Baseline separation | Very slight or no valley | ~0.1% overlap [6] | Standard for reliable quantification [6] |

| Rₛ = 2.0 | High separation | Complete baseline separation | Negligible | Excellent for quantification of complex mixtures |

The Fundamental Resolution Factor Equation

For method development, the most powerful form of the resolution equation breaks Rₛ down into its three fundamental chromatographic parameters:

Rₛ = (√N / 4) × [(α - 1) / α] × [k₂ / (1 + k₂)]

Where:

- N is the column efficiency (theoretical plate number).

- α (alpha) is the selectivity or separation factor (k₂/k₁ for two adjacent peaks).

- k is the retention factor of the later-eluting peak [50] [51].

This equation is the key to systematic troubleshooting and method optimization, as it isolates the three levers a chromatographer can control.

The logical relationship between the fundamental factors and the goal of achieving high resolution can be visualized in the following workflow:

Troubleshooting Guides & FAQs

This section addresses common issues researchers face during method development for residual solvent analysis, with a focus on practical solutions derived from the resolution equation.

Frequently Asked Questions

FAQ 1: What is the minimum resolution required for reliable quantification of residual solvents? For reliable quantification, a baseline resolution of Rₛ ≥ 1.5 is generally required [6]. At this value, the overlap of two equal Gaussian peaks is only about 0.1%, which minimizes quantification errors. While an Rₛ of 1.0 may be sufficient for qualitative identification, methods intended for compliance reporting (e.g., following ICH Q3C or USP <467>) should target baseline resolution [18].

FAQ 2: My peaks are co-eluting (Rₛ ≈ 0). Which parameter should I adjust first? Your first and most effective step should be to try to increase the selectivity (α). This has the most powerful effect on resolution because it directly increases the distance between the peaks [51]. This can be achieved by changing the chemical nature of your separation, for instance, by switching the stationary phase (e.g., from a C18 to a polar-embedded phase) or, in GC, by changing the column chemistry (e.g., from a 5% phenyl to a Wax column).